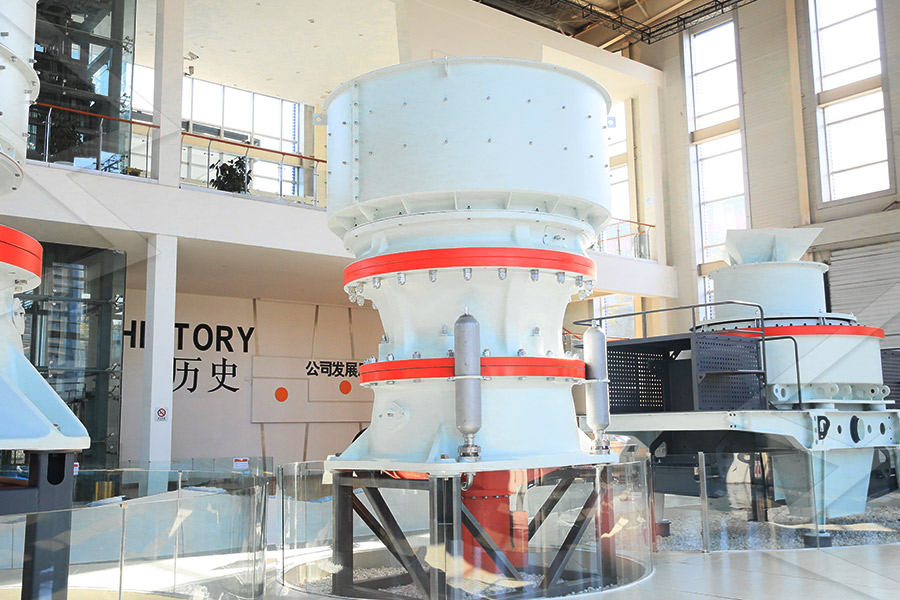

How Cone Crusher To Work 3f

制粉-10.25公众号.jpg)

How Does A Cone Crusher Work? China

Place the material you want to crush in the crusher’s feed chamber Then, when both parts of the crusher are intact, it will begin crushing The moving and stationary parts both work in a synchronized motion This motion results in This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but Cone crusher basics in 4 minutes SRP2024年3月15日 By squeezing the stuff to be crushed between a spinning cone (that’s the mantle) and a fixed bowl liner, the moving part of the cone crusher This action is crucial for churning out aggregates and turning minerals into How Does a Cone Crusher Work and What is It?2024年5月27日 The cone crusher machine has a hydraulic system to adjust the size of the discharge of the crusher The hydraulic system can effectively ensure the safe operation of the equipment When there is a foreign item in the Cone crusher working principle HAMAC

.jpg)

6 Frequently Asked Questions About Cone Crusher

2024年9月29日 The working principle of a cone crusher is based on the concept of compressive force As the material enters the crushing chamber, the mantle moves in a circular motion, 2020年6月3日 How Does a Cone Crusher Work? Cone Crusher Advantages and Disadvantages; Cone Crusher vs Jaw Crusher; How to Adjust a Cone Crusher; Cone Crusher Diagram; Choosing the Right Cone Crusher for Your A Detailed Overview of Cone Crushers and What 2024年2月26日 A compound cone crusher is a type of cone crusher that combines multiple crushing actions into one unit, making it suitable for crushing hard, mediumhard, and abrasive How does the compound cone crusher work? ZYminingLearn about the Cone Crusher! How it works, its components, design, advantages, disadvantages and applicationsCone Crushers (Parts of a Cone Crusher) Explained

4 Types of Cone Crushers: What Are They and

2024年10月14日 Ftmmachinery engineer team makes a description and comparison between the 4 types of cone crushers, to help you choose the right one cone crusher, or compound cone crusher, is an upgraded version of the 2024年10月21日 SyntroFlo is available in three standard sizes for tertiary crusher applications: STF3F, STF4F, and STF5F In addition, we are developing the STF3C, STF4C, and STF5C for secondary crushing applications Both designs work with 300 HP, 400 HP, and 500 HP cones respectively These designs will allow the SyntroFlo unit to be a cost SyntroFlo Feeders Syntron Material HandlingCone crusher has high crushing ratio, high efficiency, low energy consumption, uniform product size, suitable for medium crushing and fine crushing of various ores and rocks In the cone crusher working process will encounter a variety 14 Cone Crusher Common Problems And How 2024年3月19日 To wrap it up, a cone crusher diagram is a seriously useful way to see and understand the main parts and how these awesome crushing machines work By really getting to know the nittygritty of cone crusher Cone Crusher Diagram: Simplified Guide JXSC

.jpg)

rock crusher namibia 3f compsat

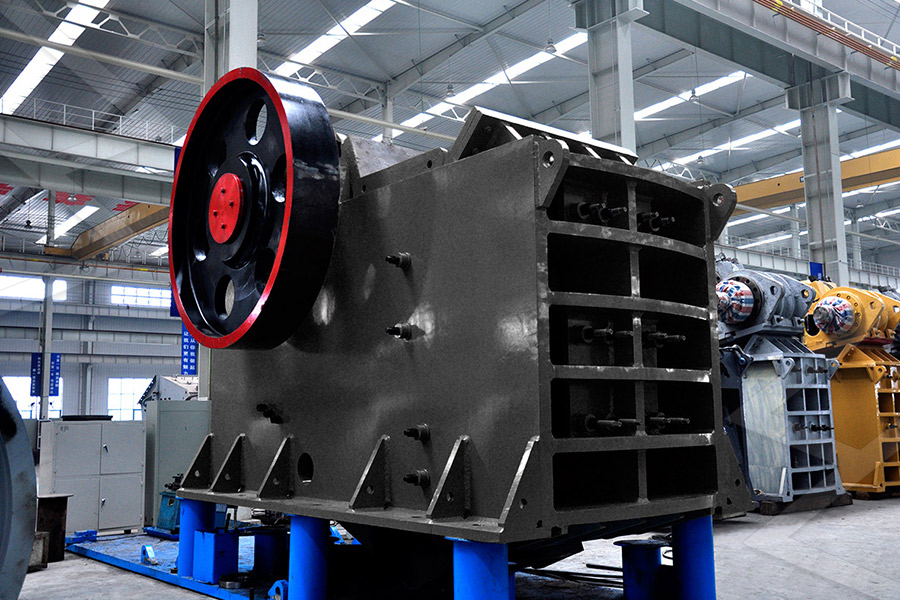

How Cone Crusher To Work 3f cone crusher 60 3f tubize2002 metallurgical content crusher selection crusher design crusher installationcrusher coststhe crushers rock breakersarea of appliion here is a list of rules of thumb often used in rock crushing and around crushers crusher selection for a hard rock mine appliion below 600 tonneshour select 2023年2月21日 Cone crushers are commonly used in the mining and aggregates industries to reduce the size of raw materials, such as rocks and minerals These machines are powerful, efficient, and versatile, but they rely on highquality wear parts to function effectively In particular, the cone crusher liners, also known as concave and mantle liners, play a crucial role in the Ultimate Guide to Cone Crusher Liners: Materials, Designs2021年11月22日 Important differences in design show up visually when a crosssection of the crushing chamber of a conventional crusher is superimposed over that of the crusher Now you can see the advantages of the 1 /3 deeper chamber using nonchoking jaw platesHow does a Rock Crusher Work Jaw Crusher2017年4月7日 A cone crusher punishes itself in every minute of operation It squeezes a dense mass between heavy castings until the mass disintegrates It abrades and minces aggregate until the material yields to the applied forces It rumbles and vibrates and bangs as its core shaft spins eccentrically to capture and reduce chunks of aggregateCaring for your cone crusher: A guide to optimising performance

How Does a Crusher Work Multico Prime Power Inc

2023年4月18日 How Does a Crusher Work April 18, 2023 What are the different stages a stone crushes takes to crush rocks? Feeding; Crushing; Screening; Segregation; Crushers are heavyduty machines specifically designed to break down large solid materials into smaller and more manageable pieces In the Philippines, they are used to utilize different forms of natural 2023年2月21日 In this comprehensive guide, we'll explain the working principle of a cone crusher, its components, maintenance tips, benefits, and offer practical advice on how to choose the right cone crusher for your application Whether you're a quarry operator or a construction contractor, this guide will help you make an informed decision when selecting Understanding the Cone Crusher Working Principle For Right The Working Process of a Cone Crusher To understand the mechanism of a cone crusher, it’s essential to know the process behind its operation The process starts when the material is fed into the top of the crusher As the name suggests, the machine takes a conical approach to crushing, using an eccentric rotating movement and a concave What Is The Mechanism Of Cone Crusher? Caldas 2023年2月28日 How Gyratory Cone Crushers Work A gyratory cone crusher consists of a mantle and a concave surface, which are both lined with wearresistant materials The mantle gyrates within the concave, creating a Unveiling the Advantages and Applications of

What Are Rock Crushers and How Do They

2024年4月19日 A shorthead cone crusher has a short crushing chamber and it is designed for the production of finer output sizes, generally between 6 mm and 25 mm A fine cone crusher, also known as a tertiary cone crusher, is used for 2024年10月22日 Superior’s Patriot Cone Crusher is an Americanmade, bushingstyle rock crusher that sets the standard for productivity and durability With a lifetime warranty and highgrade, industryexceeding components, the Patriot Cone delivers reliable performance and unbeatable value in secondary or tertiary applicationsPatriot® Cone Crusher Superior IndustriesBasic Structure: A hydraulic cone crusher consists of a frame, transmission, eccentric sleeve, bowlshaped bearing, crushing cone, mantle, adjusting device, adjusting sleeve, hydraulic control system, hydraulic safety system, and other components Crushing Principle: The main shaft of the hydraulic cone crusher is suspended on the top of the frameWhat is a hydraulic cone crusher and how does it work5 天之前 In the working process of the cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates and swings under the forced movement of the eccentric shaft sleeve The static cone is broken by multiple squeezing and impacts When the moving cone leaves this section, the material that has Cone Crusher For Sale in Indonesia Price from$23,880 12

Prolonging Cone Crusher Liners Working Life Precision

Latest News 5 common materials for blow bars 18 1 月, 2022 9:40 上午; When How To Change Jaw Plates? 18 1 月, 2022 9:33 上午 Prolonging Cone Crusher Liners Working Life 18 1 月, 2022 9:25 上午; Cone Crusher Maintenance 18 1 月, 2022 9:06 上午; Famous Cone Crusher Brands 18 1 月, 2022 8:58 上午; Categories2021年4月16日 Tertiary cone crusher configurations typically work with a reduction ratio of 25:1 to 4:1 The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per cent will pass (P80) The reduction ratio for tough, high strength, damp material is restricted to the low The pros and cons of cone crusher applications Quarry2012年8月15日 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more Cone Crusher Engineering Intro2022年3月22日 The operation procedure of cone crusher At present, the common cone crushers are mainly the single toggle cone crusher and compound cone crusher (Symons cone crusher) Although both types of cone crushers Cone Crusher Tips of Operation and Regular

A Comprehensive Guide to Cone Crusher Types

2023年2月15日 The mobile cone crusher is designed to be easily transported between sites and is usually mounted on tracks, which provides flexibility in terms of the types of terrain that it can operate on Furthermore, mobile cone 2016年4月7日 A cone crusher is punished during every minute of operation It squeezes a dense mass between heavy castings until the mass disintegrates It impacts and abrades material until it yields to the applied forces It rumbles and vibrates and bangs as its core shaft spins eccentrically to capture and destroy chunks of stoneSix steps to improve cone crusher performance Quarry2023年2月24日 Introduction A cone crusher is a type of crushing equipment used in mining and aggregate industries It works by compressing materials between a mantle and a concave, which causes them to break apart Proper adjustment of a cone crusher is crucial for its efficient operation and to ensure that it produces the desired product sizeHow to Adjust a Cone Crusher: A StepbyStep Guide for 2024年10月27日 Keestrack's Cone Crusher range are Hybrid powered, which in comparison to regular dieselpowered Cone Crusher uses 50% less fuel By integrating EMotors energy, efficiency is boosted to 95% over hydraulic motors that are only 75% efficient Automation Sensors located throughout the machine monitor load, fill levels and capacityHow Keestrack Cone Crushers Work Blog Equip2

.jpg)

Gyratory Crushers vs Cone Crushers: Which is More Efficient

2024年7月25日 How Cone Crushers Work Cone crushers are used in secondary, tertiary and quaternary stages of crushing after the initial crushing of the material by gyratory crushers and jaw crusher These crushers are of a cone shape with a mantle that rotates in a bowl and the rocks are crushed by the action of the mantle compressing them between the mantle 2020年6月23日 Cone Crushers were developed more than a century ago to provide secondary, tertiary and even quaternary material reduction Like other compression crushers, Cone Crushers feature a crushing chamber or cavity where the rock is crushed to a smaller sizeThe crushing chamber in a Cone Crusher is the space created between the mantle (the moving piece of Cone Crusher Liners: How to Select and When to ChangeCone crusher working principle and type Cone Crusher Cone Crusher broken parts are expected to block the work of two truncated cone One is the dynamic cone , fixed on the spindle; the other, said fixed cone cone crusher,spring cone crusher,cone crusher working principleCone Crusher Working PrincipleA Cone Crusher with coarsestyle liners would typically have a 6:1 reduction ratio, though reduction ratios of 8:1 may be possible in certain coarse crushing applications Fine liner configurations typically have reduction ratios of 4:1 to 6:1 How CMB Cones Crushers Work CMB Cone Crushers feature a lower mainframe housing the main shaft CMB Cone Crushers McLanahan

Cone Crusher an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher, and accordingly many of the same terms including gape, set, and throw, apply The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 68)Major suppliers of cone crushers include Metso 2022年8月26日 work a cone crusher needs to do “Many operations try to do too much with one machine, pushing it beyond its design limitations; and causing excessive component stress and wear, and the potential of serious damage,” says Schultz All crushers are designed for certain reduction ratio limitations In mostMaximizing Cone Crusher Performance Machinery Supply2015年6月16日 Sizing a crusher can be done reliably calculated thanks to the Impact/Crushing Work Index and the testwork research done by Fred Chester Bond and his 1952 paper According to Bond’s Third Theory of Comminution, Bond Impact Crushing Work Index Procedure 2023年2月24日 Hydraulic cone crushers are powerful machines that are widely used in mining, construction, and other industries In this article, we will explain the mechanics of hydraulic cone crushers, their types, applications, and maintenance requirements We will also address some frequently asked questions about these machines to help you make an informed decision Everything You Need to Know About Hydraulic Cone Crusher

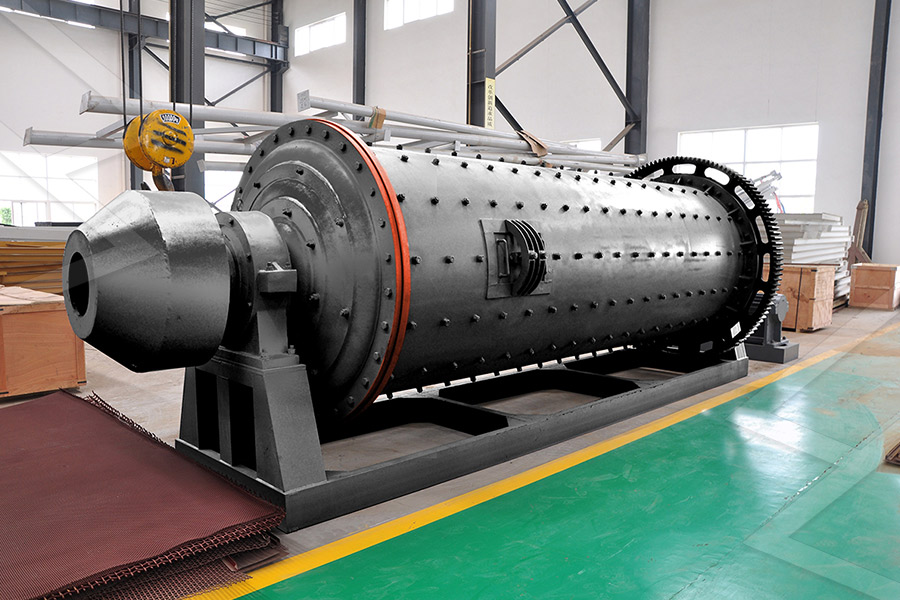

Working Principle of Cone Crushers maden

Essentially, cone crushers have a cylindrical body with a conical head designed to compress and crush materials within This head rotates thanks to an eccentric shaft, allowing for the crushing of stones Working principle of cone crushers Working Principle of Cone Crushers Feeding Stage: Stones are fed into the cone crusher2015年5月13日 The work has been carried out at Machine and V ehicle Design, Chalmers University of T echnology cone crusher already at the design stage would enable improvements without fullscale testing(PDF) Cone Crusher Performance ResearchGate2019年10月30日 There are jaw crusher, gyratory crusher and cone crusher which work by extrusion principle Hammer crusher and impact crusher working on impact principle The roller crusher works by shearing and extrusion principle The hammer crusher and impact crusher are the most common type used in the cement industry Both of them rely on the impact How To Choose Cement Crusher? Jaw Crusher, Cone Crusher 2024年2月5日 Cone Crusher, Impact Crusher: Usually between 125 mm and 150 mm: Further reduced to 20 mm to 40 mm The material from the primary crusher is fed into secondary crushers for a more uniform and finer size Tertiary Crushing: To obtain even finer material suitable for specific requirements Fine Jaw Crushers, Cone CrushersHow Does a Jaw Crusher Work? A Simple Guide JXSC

.jpg)

Influence of Two Mass Variables on Inertia Cone Crusher

2021年2月4日 Inertia cone crushers are widely used in complex ore mineral processing The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher Particularly the operative crushing force of the moving cone and the amplitude of the fixed cone are affected, and thus the energy consumption of the crusher In 2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several mineralogical, physico Evaluation of size reduction process for rock aggregates in cone crusher