Application Of Polyurethane In Ball Mills

.jpg)

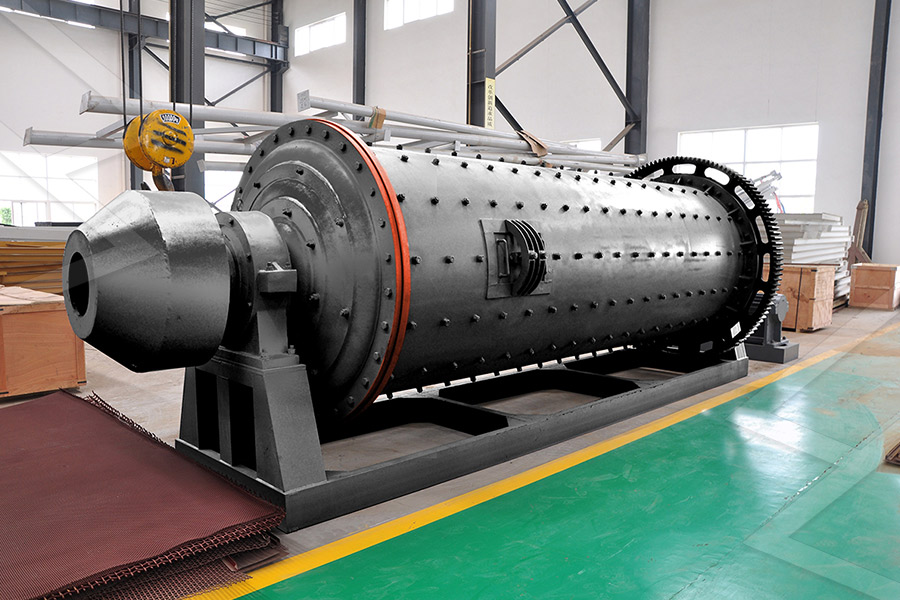

Ball Mill Application and Design Paul O Abbe

Our polyurethane mills utilize a proprietary casting method using a fabricated steel mold placed in the mill cylinder creating a 1” void on all sides Deaerated polyurethane is poured in the space between the mold and cylinder ABBE Jar 2024年6月7日 Ball milling has the capacity to change materials’ crystal structure, specific surface areas, pore volumes, and particle sizes and even promote grafting reactions to obtain functional groups to surfaces This Recent Advances in BallMilled Materials and 2013年8月1日 Using the buildingkit chemistry of polyurethane synthesis, similar high performance elastomers were used to extend the life time of ball mills An intelligent system Field Experience with Novel High Performance Polyurethane 2021年10月18日 In this review paper, the synthesis method, chemical structure, and engineering properties of PU materials were first introduced briefly Secondly, the practical Recent applications and developments of Polyurethane

.jpg)

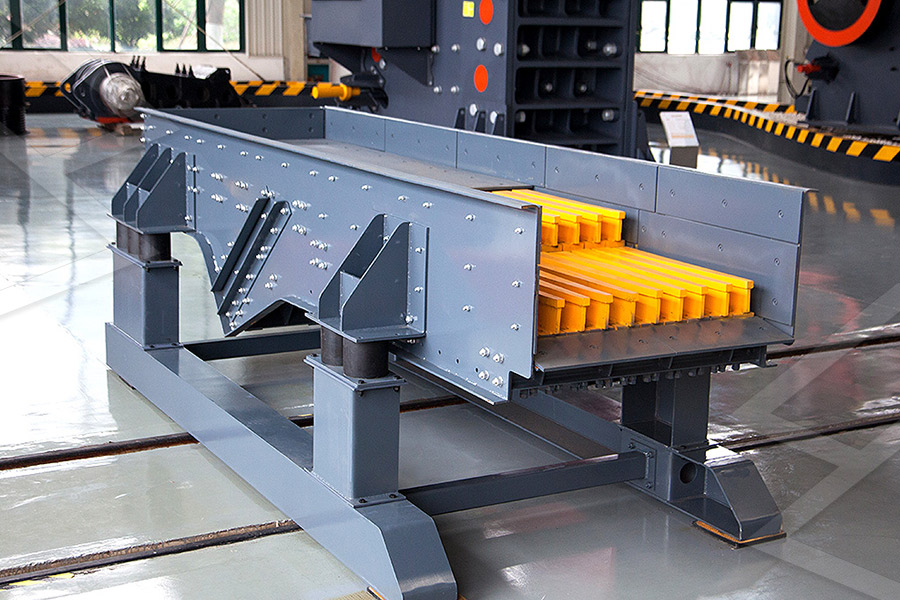

The liners are made of wear resistant TEKNIKUM®

2022年5月11日 Teknikum® Polyurethane Mill Linings are made of highly wear resistant polyurethane compounds that were specially developed for various mining and grinding mill 2023年6月29日 In this review, we summarize the progress made in utilizing simple ball milling (an important type of mechanochemical approach) to fabricate flame retardants and flameretardant polymer compositesFacile Ball Milling Preparation of Flame 2020年7月1日 Proper modifications in the raw material can hence produce a polyurethane virtually suitable for every application The study here throws light upon the basic chemistry of A brief discussion on advances in polyurethane applicationsPolyurethane Ball mill is mainly used to pulverize polyurethane materials to the required particle size, for the preparation of polyurethane foam, resilience body, sealing parts and other productsPolyurethane Ball mill NBCHAO

Facile Ball Milling Preparation of FlameRetardant Polymer

2023年6月29日 In this review, we summarize the progress made in utilizing simple ball milling (an important type of mechanochemical approach) to fabricate flame retardants and flame 1 天前 The increasing focus on sustainable construction is driving the industry toward materials that combine functionality with environmental benefits A viable approach to address this demand is the use of biobased additives to improve Characterization and Performance Enhancement 2021年8月11日 highchromium white iron linings are specifically developed for mill lining applications and are carefully selected based on the operating conditions of each mill and the discharge system The concept is best suited for large AG, SAG and ball mills with large trunnions and where modern liner handlers are available polyurethane Mill lining solutions for horizontal MetsoThis chapter is designed to discuss modeling of creep and viscoelasticity If a Polyurethane (PU) foam car seat creeps, the driver's eye position sinks with respect to the rearview mirror and the mirror needs to be adjusted In orthopedic seating and mattress applications, there is creep loading for long hoursPolymer Foams Handbook ScienceDirect

Polyurethane Ball Mill Jar with Lid Landt

4 天之前 Polyurethane ball milling jars are wareresistant with excellent performance in the areas of the electronic industry and battery materials Skip to content Battery Test Equipment Supplies PRODUCT Menu Toggle The applications of ball mills are diverse and encompass a wide range of industries and scientific research fields These versatile milling machines are used for various processes including grinding, mechanical alloying, and material property alteration Let's delve into the practical applications of ball mills in the context of mining ores Understanding the Advantages and Disadvantages of Ball Mills Pebble Mill Application and Design Pebble mills also known now as ceramic lined mills are a type of ball mill and are used in the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, minerals for ceramics and semiconductor materials down to 1 micron or less Polyurethane Lined MillsPebble Mill Application and Design pauloabbe2012年6月1日 The applications of ball mills are ubiquitous in mineral processing and mining industry, metallurgy, cement production, chemical industry, Ball mills can grind a wide range of materials (PDF) Grinding in Ball Mills: Modeling and Process Control

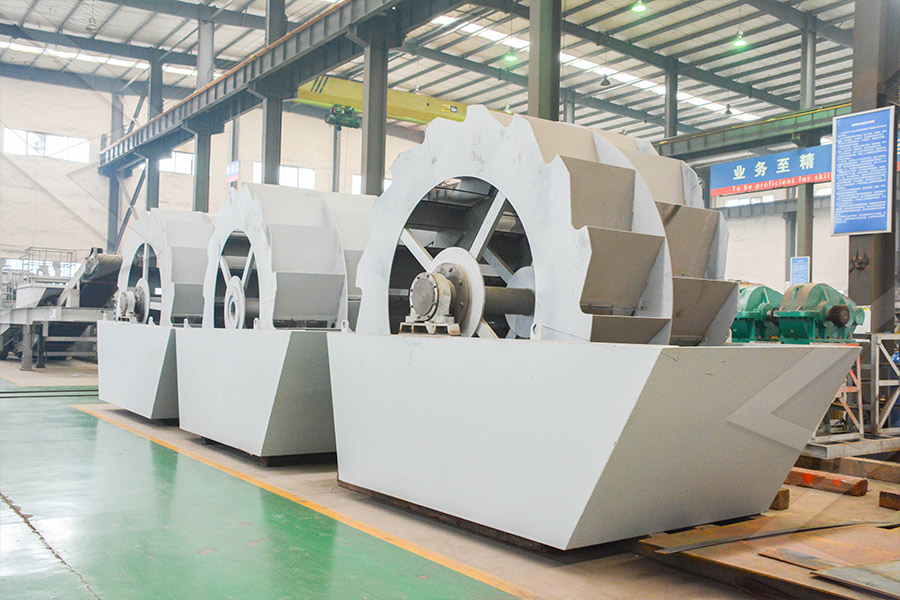

Mill Lining Systems FluidHandling Trelleborg

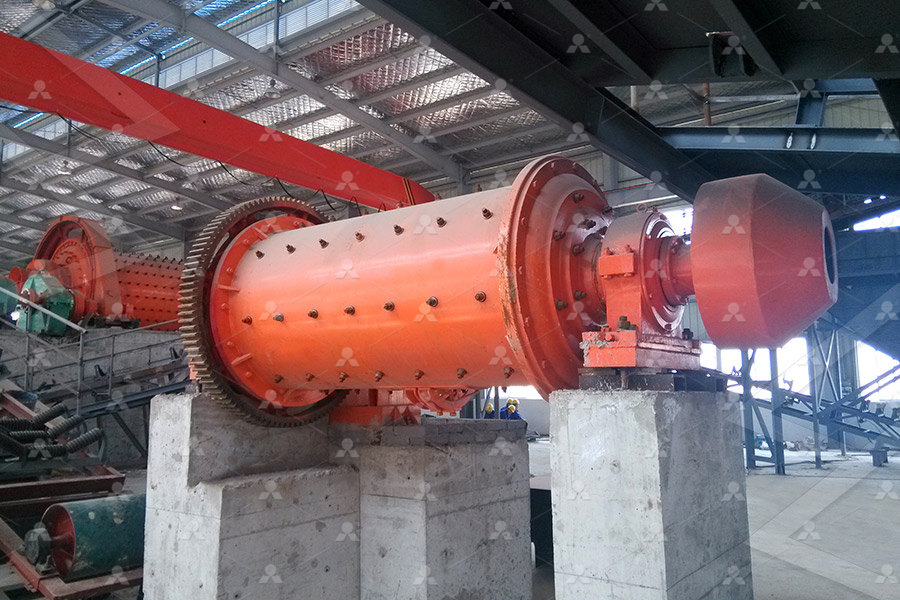

Grinding mills play a key role in comminution and mineral dressing and are subjected to severe impact and abrasion Trelleborg designs and manufactures auxillary wear components and accessories for AG, SAG, ball mills and scrubbersSize Reduction Mill Application and Design Steel ball mills and ceramic lined mills are used the size reduction of hard materials such as minerals, glass, advanced ceramics, metal oxides and semiconductor materials down to 1 micron or less Our polyurethane mills utilize a proprietary casting method using a fabricated steel mold placed in Size Reduction Mill Application and Design Paul O Abbe2021年10月18日 It is widely believed that Otto Bayer and his coworkers were one of the pioneers in conducting PU research in 1937 at the IG Farben lab in Leverkusen, Germany [19]The largescale industrial production and application of PU materials began in the 1950 s, as the polyisocyanates (one essential raw material for PU synthesis) became commercially Recent applications and developments of Polyurethane 2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties(PDF) Grinding Media in Ball MillsA Review ResearchGate

.jpg)

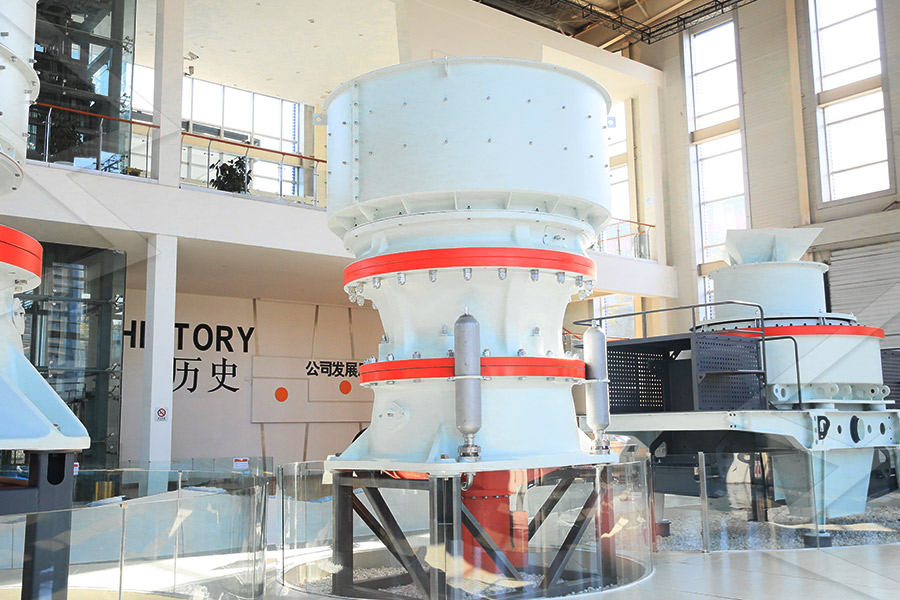

BALL MILLS FROM NANO GRINDING TO

2019年12月11日 Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available 2022年5月11日 TEKNIKUM® Polyurethane Mill Linings Teknikum® Polyurethane Mill Linings are made of highly wear resistant polyurethane compounds that were specially developed for various mining and grinding mill applications The polyurethane mill linings are best suited for ball mill secondary stage grinding process All polyurethane mill linings areThe liners are made of wear resistant TEKNIKUM® 2007年9月1日 Ball mill grinding circuit is essentially a multiinput–multioutput (MIMO) system with strong coupling among process variables Simplified model with multiloop decoupled PID control usually cannot maintain a longtime stable control in real practice After a brief description of MPC scheme in Section 3, an industrial application with Application of model predictive control in ball mill grinding circuit2024年10月11日 Polyurethane ball milling jars are wareresistant with excellent performance in the areas of the electronic industry and battery materials You're viewing: Polyurethane Ball Mill Jar with Lid $ 13000 – $ 99900 Select options Polyurethane Ball Mill Jar with Lid Primet Lab

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to 2022年11月30日 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size Ball Mill: Operating principles, components, Uses, 2016年1月1日 The wear of balls used during a grinding process is considered one of the losses that cause an increase in the operating cost allocated to the ball mill [21] Ball wear occurs due to abrasion (PDF) A comparison of wear rates of ball mill grinding media2024年10月30日 High energy planetary Ball Mills are designed for fine grinding, mixing, and preparing a small volume of materials, which feature high efficiency, low noise, and small batches Polyurethane Ball Mill Jar with Lid $ 13000 – $ 99900 Select options This product has multiple variants The options may be chosen on the product pageBall Mill Primet Lab

Ball milling : A green technology for the preparation and

2019年1月9日 Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the preparation 2024年2月20日 With a range of different laboratory ball mills on offer, they are predominantly used in research and development applications However, if ball mills are able to accommodate the requisite amounts of material for processing, laboratory mills are occasionally deployed in smallscale battery production pilot plantsHow Ball Mills Contribute to Battery Technology AZoMOur polyurethane mills utilize a proprietary casting method using a fabricated steel mold placed in the mill cylinder creating a 1” void on all sides Deaerated polyurethane is poured in the space between the mold and cylinder Polyurethane Lined Mill Paul O Abbé2019年10月19日 Ball mills are extensively used in the size reduction process of different ores and minerals The fill level inside a ball mill is a crucial parameter which needs to be monitored regularly for optimal operation of the ball mill In this paper, a vibration monitoringbased method is proposed and tested for estimating the fill level inside a laboratoryscale ball mill A vibration Monitoring the fill level of a ball mill using vibration sensing

.jpg)

Recent advances in the treatment of contaminated soils by ball

2022年3月15日 For scaleup applications, the jars of planetary ball mill must have led to elevated energy consumption due to volume and mass gains Additionally, the planetary ball mill uses inertial forces generated by rotation to drive the grinding ball, but centripetal forces tangent to gravity make part of the gravitational potential energy wasted 2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a (PDF) Effects of Ball Size Distribution and Mill Speed and 2021年11月1日 High chromium balls are recognized as better grinding media in terms of wear rates than forged steel balls, which are conventional grinding media in the milling process of iron oreMorphology and wear of high chromium and austempered ductile iron balls 2024年1月21日 Abstract The construction sector is a prominent resourceintensive industry on a global scale, contributing significantly to environmental challenges through material production and construction operations Selecting sustainable and energyefficient building materials is crucial, considering green sustainable construction Over the past two decades, polyurethane Redefining Construction: An InDepth Review of Sustainable Polyurethane

Unlocking the potential: The role of Ball Mills in battery

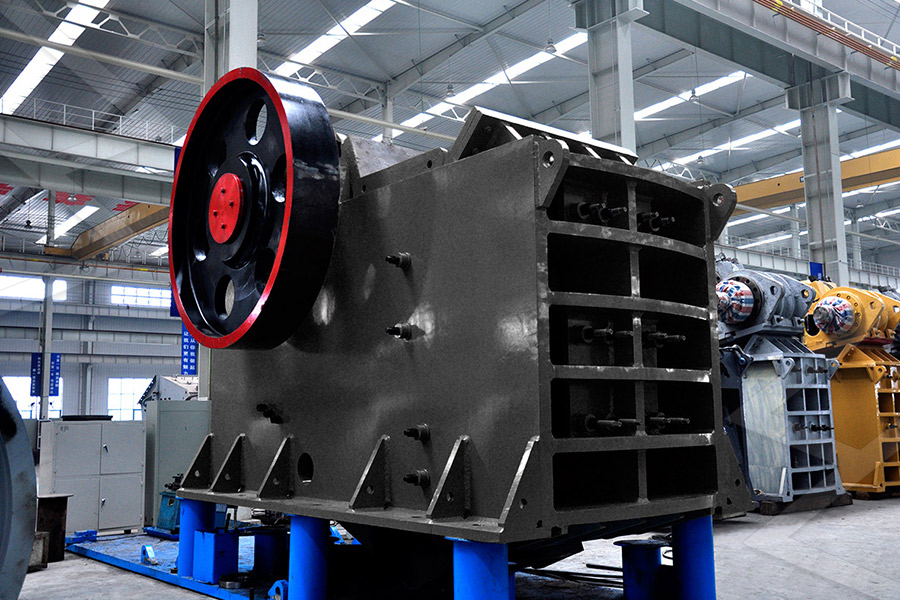

which is induced by the kinetic energy of a ball mill In the HighEnergy Ball Mill Emax for example, an unrivalled acceleration of 76 g can be obtained, if running at its maximum speed of 2000 rpm SELECTING THE MOST SUITABLE BALL MILL To identify the most suitable ball mill for a particular application, the task and required out 2015年11月30日 A ball mill consists of a hollow cylindrical shell that rotates about its axis, with balls occupying 3050% of the volume to facilitate grinding as the shell rotates Applications of ball mills include grinding metallic powders, carbon, coal, cement, fertilizers and other materials Read lessBall Mill PPT SlideShare2023年10月24日 The Lining Plate Of Ball Mill Is Gradually Replaced By Rubber And Polyurethane Lining Plate In China, But With The Continuous Application Of Rubber Polyurethane Lining Plate In The Lining Plate Of Ball Mill, It Has Gradually Replaced Manganese Steel And Other Lining Plates And Become The Mainstream Of Market DevelopmentBall Mill Liner ( Rubber , Polyurethane ) Mill Rubber Linings Plate Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product Charging a Dry Mill The general operation of a grinding mill is to have the product impacted between the balls as Ball Mill Loading Dry Milling Paul O Abbe

.jpg)

Application of Dry Ball Milling in Mineral Processing

2024年3月7日 The application of drygrinding ball mills in mineral processing provides significant advantages in terms of costeffectiveness, environmental sustainability, and process control These benefits make the ball milling process a preferred method for refining and processing raw materials in the mining industry, offering a more efficient and Ball mill media, such as alumina or zirconia balls, grind and blend the powders This process finds applications in the pharmaceuticals, ceramics, chemicals, and metallurgy industries It enables efficient size reduction, mixing, and homogenization of High Energy Ball Mill For Sale Vertical Ball Milling MachineThe ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral Crosssection of typical ball mills showing 2022年10月17日 Ball Mill Price in India ranges from 53,000 to 120 Lac depends on the size Naresh Bhakar Naresh Bhakar is the Founder and Author at Pharmaguddu, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide He has experience in Pharma manufacturing and has worked with top PharmaceuticalsBall Mill; Principle, Working, and Construction » Pharmaguddu

Polyurethane Rubber Resin Balls Precision Plastic Ball

Precision Plastic Ball is a supplier of polyurethane balls floating spheres used for sporting equipment, caster wheels, gears more Contact us today! The store will not work correctly in the case when cookies are disabled and tear properties It meets the terms of FDA foodcontact regulations 21 CFR 1771680 and 1772600 The primary 2024年7月12日 Unlock ball mill technology Discover how these versatile machines are used for industries for grinding and blending materials efficiently the decision between wet and dry grinding will be determined by the specific requirements and constraints of the application in question Ball Mill Varieties There is a diverse array of mill varieties What Is a Ball Mill and How Does It Work? (Overview 2024)Polyurethane foam balls Polyurethane foam balls are known for their soft, squishy texture and their ability to bounce back to their original shape after being squeezed or compressed They are available in a wide range of sizes, colors, and densities, making them suitable for a variety of different applications In addition to their use as Polyurethane foam balls smpu foamWith over 60+ years of experience in manufacturing grinding solutions, we are a leading manufacturer and supplier of ball mills tailored for mineral applications Our ball mills are engineered to provide superior performance, durability, and energy efficiency Here are some key reasons why Chanderpur Group’s ball mills stand out: 1Advanced Technology Ball Mills for Mineral Applications

.jpg)

Ball Mills in the Mineral Processing Industry MechProTech

2024年5月27日 Applications of Ball Mills in Mineral Processing Ball mills are widely used in the beneficiation process for various ores and minerals, including gold, copper, iron, and zinc They fall part of the comminution process, where ores are crushed to separate valuable minerals from the gangue In mineral processing plants, ball mills are employed in 2019年11月1日 Rasouli Pirouzian, Peighambardoust, and Azadmard Damirchi (2017) evaluated the optimized formulation of sucrosefree milk chocolate containing maltitol and xylitol by applying ball mill However compound chocolate was obtained from ball mill, also the differences exist in the formulation and the type of ball mill that were usedApplication of simplex lattice mixture design for optimization