Different Makes Of Cone Crushers

A Detailed Overview of Cone Crushers and What You Need

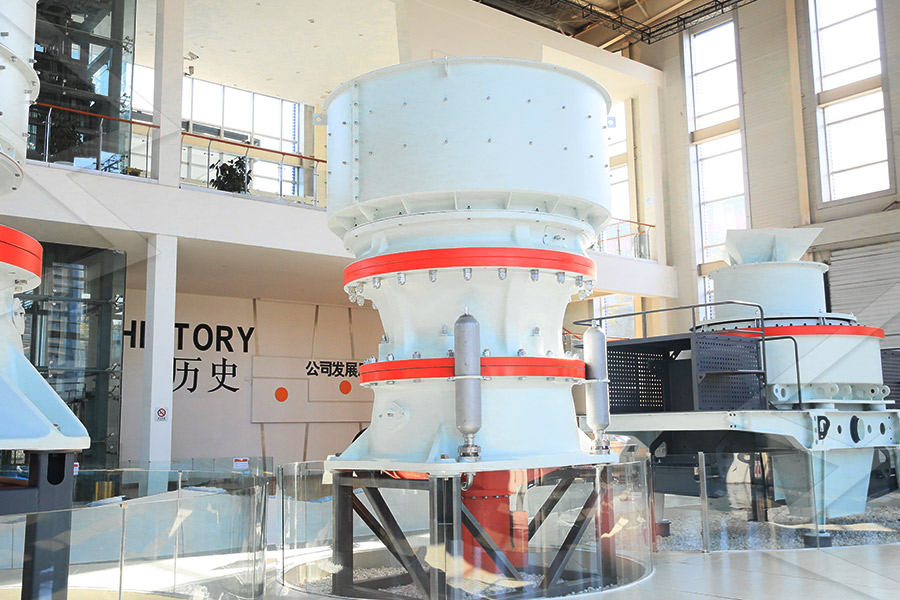

2020年6月3日 Cone crushers are one of the most versatile pieces of crushing equipment available, and you'll find cone crushers across a variety of different industries, from mining to concrete to recycling and moreThe cone crusher is a modified gyratory crusher, and accordingly many of the same terms including gape, set, and throw, apply The essential difference is that the shorter spindle of the Cone Crusher an overview ScienceDirect Topics2024年7月15日 Cone crusher is an important production equipment for fine crushing process in mine crushing production The performance of cone crusher is closely related to the correct What is a Cone Crusher?SBM Industrial Technology Group2024年9月29日 The main parts of a cone crusher include the fixed cone liner, movable cone liner, transmission shaft, adjustable discharge opening, frame, and eccentric bush or shaft 6 Frequently Asked Questions About Cone Crusher

Cone Crushers: Types, Benefits, and Applications in Mining

2018年6月1日 Essentially, cone crushers can be classified into distinct types, depending on their duty Crusher sizes for all duties are described by terms arising out of common industry usage, 2019年10月9日 This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one JXSC engineer team does help you to buy the cone crusher, and design a complete crushing circuit5 Types of Cone Crushers Comparison JXSC 2023年3月17日 Compound cone crusher (also known as Simmons cone crusher) includes the standard and short head types Generally speaking, the standard type is suitable for coarse Discover the Different Types of Cone Crusher JXSC Mineral5 Common Types Of Cone Crusher The cone crusher plays a significant role in the mining industry, with advantages such as high crushing force, high work efficiency, simple structure, easy maintenance, and easy operation and 5 Common Types Of Cone Crusher JXSC Rock

What Are The Different Types Of Crushers?

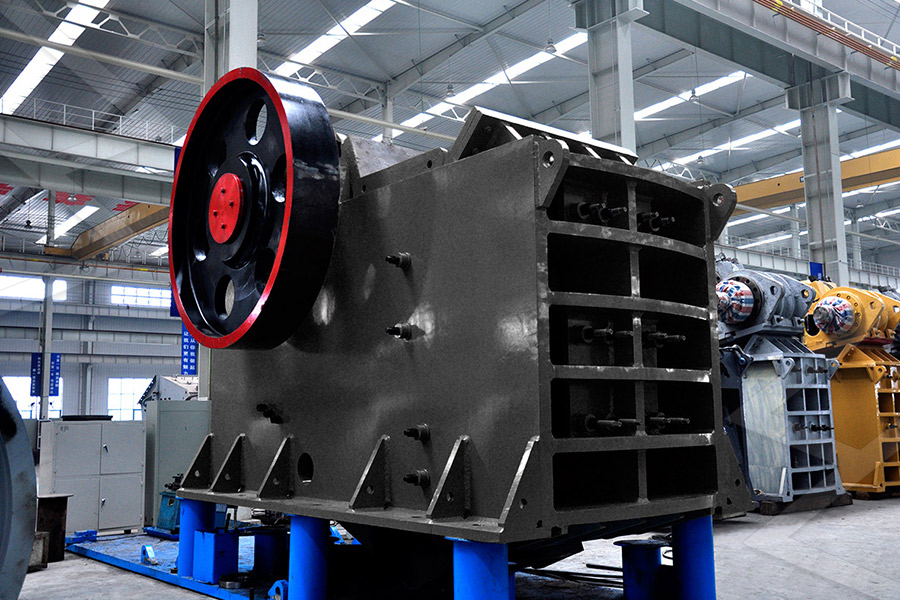

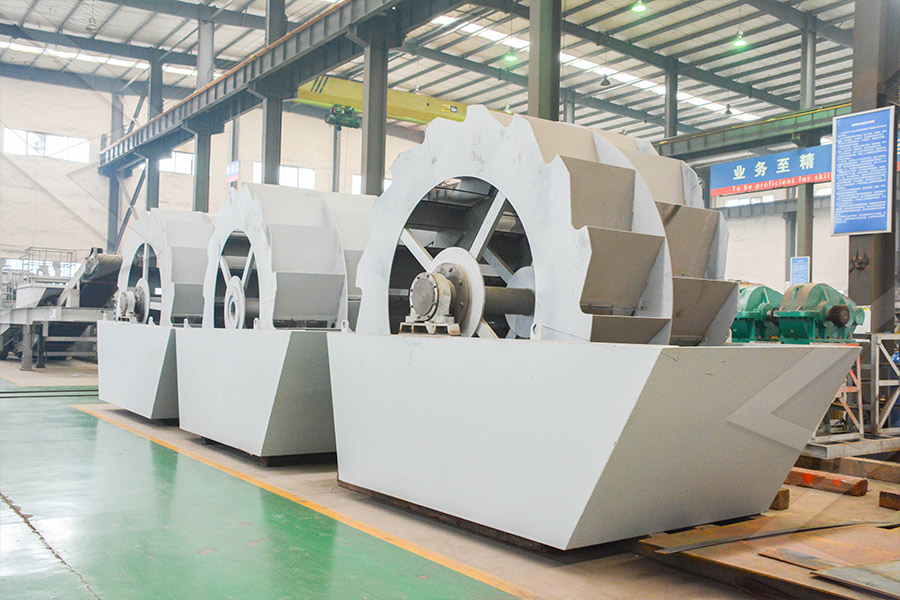

2024年10月31日 In terms of capacity, jaw crushers can process up to 1,600 tons of material per hour 2 Cone Crushers Cone crushers are types of crushers that are generally used in mining, aggregate production, and construction A 2024年7月17日 Secondary crushers include cone crushers and impact crushers Cone Crusher Cone crushers utilize lamination crushing, where material enters the crushing chamber from the top and is compressed and ground into smaller particles between the moving cone and the fixed cone until it is discharged from the bottomTypes of Crushers: Choosing the Right One for Each Stage3 天之前 Of course, there are also different styles of rock crushers Compressionstyle jaw and cone crushers, for example, fit into the various stations in a crushing circuit (depending on factors like the sizes, varieties, Types of Rock Crushers Quarry Crushing 2023年2月15日 There are several different types of cone crushers available, each with its own unique set of features and advantages In this article, we’ll take a closer look at the most popular types of cone crushers on the market Spring Cone Crusher The spring cone crusher is one of the oldest and most widely used cone crushers on the marketA Comprehensive Guide to Cone Crusher Types AGICO

.jpg)

How Does a Cone Crusher Work and What is It? JXSC

2024年3月15日 What makes cone crushers stand out is their ability to tackle the next phases of crushing, shaving down material to the exact size and shape needed For harder basalt, with a Mohs hardness of around 56, it can make the pieces even smaller This versatility means cone crushers can be used in different stages of the crushing process 2020年12月17日 Cone crushers resemble gyratory crushers from the technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not neededCrushing 101 – Different types of crushers for distinctive needs2024年3月19日 Cone crushers can be fed in different directions They often connect to other machines, like conveyor belts, for moving and processing materials The eccentric shaft, powered by the crusher’s motor, makes the mantle move in a circular, backandforth motion This creates compression and release cycles inside the chamberCone Crusher Diagram: Simplified Guide JXSC2021年2月24日 Spring Cone Crushers Spring cone crushers are able to compress things over medium hardness and is generally used within metallurgy and the chemical industry When used in conjunction with a jaw crusher it can be used as a tertiary or quaternary crushing machine Hydraulic Cone Crushers Hydraulic cone crushers come with single cylinder and What You Need To Know About Rock Stone Crushers

Understanding the Cone Crusher Working Principle For Right

2023年2月21日 Different types of cone crushers may have specific maintenance requirements, and following the recommended maintenance schedule will help to ensure that the machine operates at peak performance which makes them ideal for highcapacity crushing applications Versatility: Cone crushers can be used for a wide range of applications, including 2023年3月6日 Abstract One of the main processes in the metallurgical, construction and mining industries is the process of grinding various materials as a primary raw materials preparation The crushing of materials to obtain the required fraction annually consumes up to 4% of the world’s electricity production, and for a single mine, the share of energy consumption for crushing can Energy Efficiency of a Cone Crusher with StopsCone Crushers Previous Next At Crusher Spares, we understand the importance of efficient and reliable crushing equipment in maximizing productivity and profitability We supply a large range of cone crushers including: single cylinder hydraulic cone crushers, high performance hydraulic cone crushers and traditional spring style cone crushers We offer both new and used equipment Cone CrushersOffering large reduction ratios with minimal fines production, Sandvik mobile cone crushers are the ideal solution for secondary and tertiary crushing Our market leading "S" type cones can accept a feed size up to 90% larger than current Mobile Cone Crushers Sandvik Mobile Cone

.jpg)

5 Types of Cone Crushers Comparison JXSC Machine

2019年10月9日 This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one Cone crusher is one of the most widely used mining equipment supply different types of rock crushers for mine, sand plant, construction industry Hot products: Jaw crusher, cone crusher, impact crusher, hammer crusher 2022年6月24日 The crushing chamber is the core component of a cone crusher, consisting of mantle and concave parts Reducing the impact of crushing chamber wear on the performance of cone crushers and the quality of crushed products while extending the service life of the mantle and concave has become a significant research challenge The impact of the compression Constant Wear Criterion for Optimization of the Crushing 2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several mineralogical, physico Evaluation of size reduction process for rock aggregates in cone 2018年6月1日 Reduction ratios normally range between 3:1 and seldom more than 5:1 In the 7ft models, the cone crusher typically makes a product all passing 2 in, but this is dependent on the machine design and properties of the material being treated crusher manufacturers normally have a range of crushers of different sizes and power ratings to Cone Crushers: Types, Benefits, and Applications in Mining

.jpg)

A review of modeling and control strategies for cone crushers

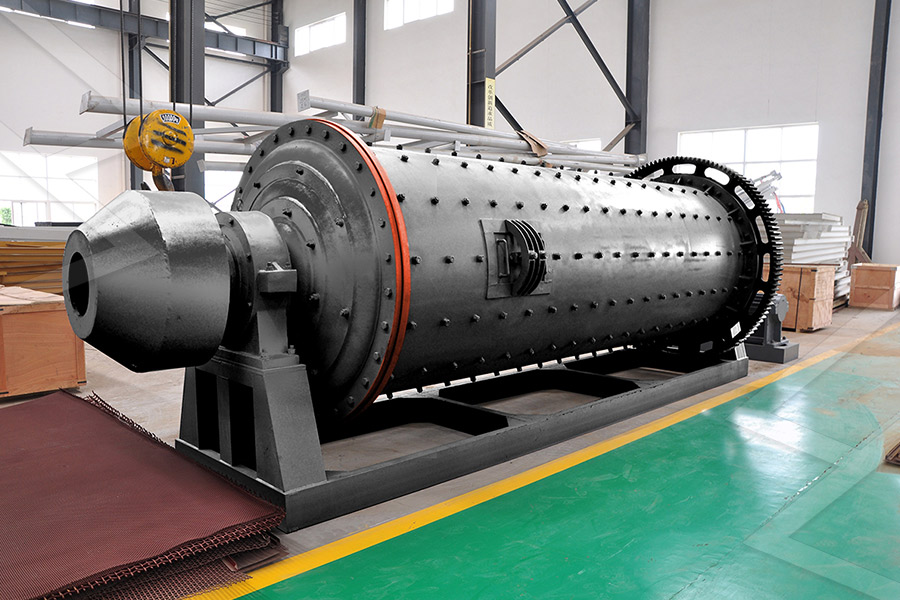

2021年8月15日 The reader is referred to Svensson and Steer (1990) for a discussion about the physics involved in rock crushing inside a cone crusher; Bearman and Briggs, 1998, Lindqvist and Evertsson, 2006 for comprehensive insights into the effect of liner wear and feed properties on the operational characteristics of cone crushers; and Wills and Finch 2023年2月22日 Stone crushers are essential equipment in mining and construction industries They are used to crush large rocks, stones, and minerals into smaller pieces or gravel for various construction purposes In this article, we will discuss the different types of stone crusher machines and their applicationsDifferent Types of Stone Crusher Machines AGICO2023年2月28日 Gyratory cone crushers are powerful machines that have revolutionized the crushing industry Their unique design and superior performance make them a popular choice for a wide range of applications, from mining and construction to recycling and chemical processing In this article, we explore the many advantages of gyratory cone crushers, including their high Unveiling the Advantages and Applications of Gyratory Cone Crushers 2023年2月22日 Stone crushers are essential equipment in mining and construction industries They are used to crush large rocks, stones, and minerals into smaller pieces or gravel for various construction purposes In this article, Different Types of Stone Crusher Machines

Unveiling the Advantages and Applications of Gyratory Cone Crushers

2023年2月28日 Gyratory cone crushers are powerful machines that have revolutionized the crushing industry Their unique design and superior performance make them a popular choice for a wide range of applications, from mining and construction to recycling and chemical processing In this article, we explore the many advantages of gyratory cone crushers, including their high 2024年6月28日 Cone Crushers Using an eccentrically gyrating spindle to break down rock enclosed in a concave hopper, cone crushers form a type of rock crusher Their versatility makes them wellsuited for use in secondary crushing Crusher Rock: Exploring the Types of Rock 2021年8月15日 The reader is referred to Svensson and Steer (1990) for a discussion about the physics involved in rock crushing inside a cone crusher; Bearman and Briggs, 1998, Lindqvist and Evertsson, 2006 for comprehensive insights into the effect of liner wear and feed properties on the operational characteristics of cone crushers; and Wills and Finch A review of modeling and control strategies for cone crushers 2024年9月14日 This design makes the Daswell cone crusher more maneuverable, stable and reliable Cone crusher price and manufacturer Different types of cone crushers have different manpower, raw materials and material resources in the production, so the price of the equipment is different If you want to know the exact quotation of Daswell crusher with Different Types Cone Crusher For Selection DASWELL

.jpg)

Prediction of Cone Crusher Performance Considering Liner

2016年12月3日 Cone crushers are used in the aggregates and mining industries to crush rock material The pressure on cone crusher liners is the key factor that influences the hydraulic pressure, power draw and liner wear In order to dynamically analyze and calculate cone crusher performance along with liner wear, a series of experiments are performed to obtain the This makes jaw crushers particularly sought after in industries that require primary crushing of hard, abrasive materials However, due to their design, they are not wellsuited for producing a final product with a cubical shape Cone Crushers Cone crushers take a different approach to crushing compared to jaw crushers Unlike their What Are The Three Types Of Crushers? Caldas Engineering 2021年8月11日 formance in the quarrying and mining industries have different optima (Lee and Evertsson, 2011) This work opens with a brief review of the mechanical principles of cone crushers Then, in the following sections, works available in the cone crusher literature, ranging from 1972 to 2020, are categorized withA review of modeling and control strategies for cone 1998年3月1日 The output prediction of cone crushers has been focused on both by the aggregate producing industry and the mining industry as the demands for higher quality and lower costs increase This fact makes optimization very interesting and challenging It is up to the aggregate producer to formulate criteria to which the optimal eccentric speed Output prediction of cone crushers ScienceDirect

Nordberg HP Series cone crushers – High performance

2023年1月20日 Ease of use is builtin to the HP Series and the design makes maintenance tasks quick, convenient and safe The crusher is easy to open, it has a very effective tramprelease Metso Outotec's Nordberg HP Series cone crushers are ideal for many different mining applications In mines, cone crushers are typically needed for crushing to obtain 6 天之前 Several primary gyratory and cone crushers have been simulated using the discrete element method Quist and Evertsson [5] investigated a Svedala H6000 industrial cone crusher through DEM and compared it to experimental data on this machine They used the commercial program EDEM with a Bonded Particle Model (BPM) to represent the fracturePredictive modeling of crushing power in cone crushers with 2024年3月20日 Jaw crushers and cone crushers are broadly utilized within the mining industry They play a significant part in mineral handling These crushers exceed expectations at breaking down different mineral minerals into littler Ultimate Comparison: Jaw Crusher vs Cone 2024年3月20日 Astec Industries is one of the best companies that makes machines and parts for mining, quarrying, and construction They have a special division called Telsmith that focuses on making crushers Telsmith makes a lot Top 10 Crusher Manufacturers for Your Mining

Application of discrete element method for simulating

2010年1月1日 PhD Thesis Cone crushers are used by both the aggregate producing and the mining industry Both industries are interested in increasing the product quality while at the same time lowering the Sandvik cone crusher series – high performance, low total cost Sandvik cone crushers are suitable for a wide range of applications within quarrying and mining segments End products for quarries include aggregates for concrete, asphalt and railway ballast Our CS and CH cone crusher series combine extremely high performance with low total costStationary cone crushers Crusher automation system SRP2023年2月28日 Cone Crushers Cone crushers are used to crush mediumhard to hard and abrasive materials, such as limestone and granite They are also used in the mining industry to crush ore Cone crushers have a rotating mantle that gyrates in the crushing chamber As the mantle rotates, it creates a squeezing action on the material, which reduces it in sizeUnderstanding the Different Types of Crushers: A 2020年3月19日 cone crushers Cone crushers, which are also known for their ability to crush hard, abrasive ores and rocks, break material by squeezing or compressing it between convex and concaveshaped surfaces Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending Selecting the right crusher for your operations Quarry

Modelling of flow in cone crushers ScienceDirect

1999年12月1日 The authors defined the size reduction by consecutive events, each with its own breakage and selection function The initial exploration of the basic operation principles of cone crushers was reported in Evertsson (1995), Evertsson and Bearman (1997), the breakage characteristics of different materials were investigated and included in the model; the concept 2021年8月11日 formance in the quarrying and mining industries have different optima (Lee and Evertsson, 2011) This work opens with a brief review of the mechanical principles of cone crushers Then, in the following sections, works available in the cone crusher literature, ranging from 1972 to 2020, are categorized withA review of modeling and control strategies for cone The Cone Crushers can easily meet different production needs by selecting crushing chambers and different eccentricities The MP Cone Crusher is an excellent choice as secondary or tertiary crushing equipment and the compact structure makes it easier for maintenance and also ideal for portable crushing plantsCone Crushers Moore Watson Ltd