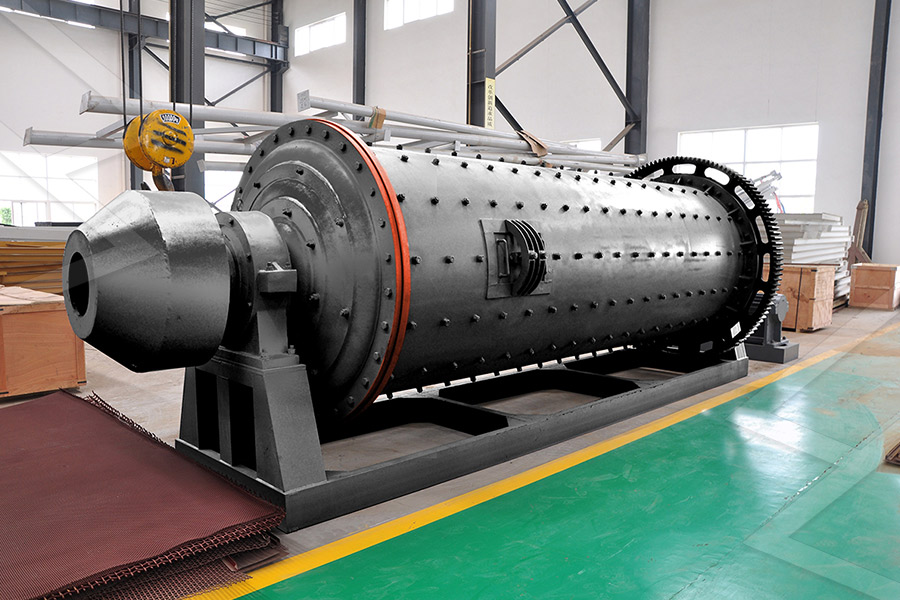

Mining Grinder Capacity 4tph Outlet Size 200mesh 1200x2400 Ball Mill

Laboratory Mineral Processing LatticeType Ball

2024年10月28日 The XMQL420*450 ball Mill is mainly composed of 420×450 lattice ball mill, 150×1200 spiral classifier, 35 liter pendulum feeder and Large Capacity 200 Mesh Mining Grinding Machine Limestone Ball Mill For Gold Manganese Iron Chromite Stone Ore , Find Complete Details about Large Capacity 200 Mesh Mining Grinding Large Capacity 200 Mesh Mining Grinding Machine Limestone Ball Mill Ball mills designed for long life and minimum maintenance Metso overflow ball mill sizes range from 5 ft x 8 ft with 75 HP to 30’ x 41’ and as much as 30,000 HP Larger ball mills are Metso Ball Mills Brochure Metso Corporation PDF 2024年10月20日 Ceramic ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, ceramics and so on It works on the principle of impact and attrition and the size reduction is done by Mining Industry Ore Processing Plant Ball Mill

Large Gold Ball Mill 200t Per Hour Capacity Ball Mill Price Mining

1 天前 Large application range, simple structure and convenient maintenance; 2 Large capacity and continuous work are obvious advantages; 3 Various barrel lining and grinding media, 2024年10月17日 200 Mesh Mining Machine Lead Manganese Iron Slag Cement Raymond Mill, Find Details and Price about Grinding Mill Machine Raymond Grinding Mill from 200 Mesh 200 Mesh Mining Machine Lead Manganese Iron Slag Cement Raymond Mill2024年10月12日 Gold Mining Machine Limestone Feldspar Quartz Copper Grinding Ball Mill for Sale US$1,80000280,00000 / Set Electrostatic Roller Separator for Complete Set Indonesia 50% Grade Zircon Sand Ore (Whole Sale Price) Mineral Processing Plant Gold 3 天之前 Capacity: 04150 t/h Feeding size: ≤2025 mm Output size: 007406 mm Get The Price Products display Introduction of ball mill The ball mill is a tumbling mill that uses steel balls as grinding media Ball mills can be used in Ball Mill Mining Grinding Mill JXSC Machinery

]@S0{UDKK%G24F3JGHC.jpg)

Exploring Ball Mill Diagram: A Comprehensive

2024年4月28日 Generally, the lengthtodiameter ratio of the mill, known as the L/D ratio, is between 05 and 3 Shorter mills are used for crushing coarse materials, while longer mills are utilized for grinding fine materials The ball APPROXIMATE CAPACITIES All ball mills operate on the same principles One of these principles is that the total weight of the charge in the millthe sum of the weight of the grinding media, the weight of the material to be ground, and any 05 TO 15 TPH SMALL SCALE MINER’S BALL MILL 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911MetallurgistBall Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to reduce Ball Mill (Ball Mills Explained) saVRee saVRee

.jpg)

Ball mill, Ball grinding mill All industrial manufacturers

A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium Applications Ball mills are found in settings as diverse as laboratories and mines, among others Technologies Ball mills can grind in either a wet or a dry environmentHow Mining and Sustainability Can Work Together Benefits of Surplus Mining Equipment What is the Circular Economy? News; 0 Home; Buy from AMKing; GRINDING EQUIPMENT; BALL MILLS ; All Categories AGITATORS MIXERS (FullerTraylor) 22' x 365' (67m x 11m) Ball Mills with Dual ABB 4,900 kW (6,662 HP) Motor Drives ACS 6000 ABB Variable Used Ballmills For Sale AM KingWith 37 years of industry experience, JXSC has built a reputation as a leading ball mill manufacturer among ball mill manufacturers Since 1985, With over 200 successful mining projects in more than 40 countries, JXSC has been providing premium services, from RD and production to installation and free operation training Applying steel balls as grinding media, Ball Mills Manufacturer JXSCThe mini ball mill is a type of smallscale ball mill grinder Compared with the industrial large ball mill, it is suitable for trial production and small batch production AGICO mini ball mills have a large grinding ratio and capacity It effectively improves the grinding fineness and output Capacity(t/h) Discharge Size(mm) Rotation Mini Ball Mill – Mineral Grinding Small Ball Mill For Sale

.jpg)

Ball Mill Grinder Ball Grinding Mill For Sale

Ball mill is one of the most variable and effective grinding machines which is mainly applied for further grinding the crushed materials Compared with other grinding mills, the variety of grinding modes, available grinding tool materials, Smaller tabletop Ball Mills such as ours are useful for grinding granular materials with a particle size up to about 1/4" into a fine dust There are some materials that our Ball Mills can grind into a powder even if the particle size is very large, like Ball Mills : United Nuclear , Scientific Equipment 2017年7月26日 The rod mill was needed to reduce feed size to the ball mill because crushing plant output was normally coarser than 80% passing 10,000 microns Such feed causes power inefficiency if fed directly to a ball millHow Ball Mill Ore Feed Size Affects Tonnage CapacityChoosing the right grinding media size, shape, and quantity can significantly improve ball mill performance Factors such as the type of grinding media and the amount of media can be optimized to achieve the desired grinding efficiency Successful ball mill optimization in the mining industry requires careful consideration of a range of Key Factors for Ball Mill Optimization in the Mining Industry

Equipment Sizing: Crusher or Grinding Mill 911Metallurgist

2016年7月8日 The Work Index values listed in Table I and II apply directly to a wet grinding overflow type rod mill 75 feet in diameter in open circuit; and to a wet grinding overflow type ball mill 75 feet in diameter in closed circuit with a rake classifier at 250% circulating load, and with 80% or more of the feed passing 4 mesh2016年6月6日 AG/SAG mills as a primary grinding stage in a circuit with or without additional stages of comminution; top size control to the ballmill circuit feed is maintained while still unloading the SAG circuit (Mosher et al, 2006) and a grate design to facilitate maximizing both pebblecrushing circuit utilization and SAG mill capacity As a SAG Mill Grinding Circuit Design 911Metallurgist2023年10月10日 The Tower Mill is another type of grinding mill used in the mining industry This vertical mill consists of a cylindrical chamber filled with grinding media, which are stirred by a shaft that moves vertically up and down Tower Mills were developed to overcome some of the limitations of both ball mills and SAG millsUnderstanding the SAG Mill in Copper Ore Mining ProcessConical Ball Mills: Also known as tapered mills, these mills have conicalshaped liners and grinding media, which increase the efficiency of grinding Conical ball mills are suitable for both coarse and fine grinding Planetary Ball Mills: These mills consist of a rotating sun wheel and one or more grinding jars, which rotate around their own Ball Mill Grinding Machines: Working Principle, Types, Parts

Mining Ball Mill Grinders Manufacturing and Suppliers in

2023年2月9日 Big Ball Mill Grinders Big ball mill grinders, on the other hand, are typically used in largescale mining operations, where high volumes of raw materials need to be processed These grinders are larger in size and have a higher capacity, making them suitable for grinding large quantities of minerals and raw materials Big ball mill grinders 2024年8月8日 In mining, a copper processing plant struggled with inefficient ore grinding using standard steel balls, leading to poor mineral recovery rates After analyzing their milling conditions, they opted for highdensity steel balls, which provided the needed impact strength to break down the copper ore more efficientlyBall Mill Success: A StepbyStep Guide to Choosing the Right Grinding If you’re in the market for a ball mill, you’re likely looking for a reliable and highquality machine that can handle a wide range of materials and processesBall mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramicsA Comprehensive Guide to Finding the Best Ball Mill for SaleGrinding is the process of achieving particle size reduction through attrition and compressive forces at the granular level The grinding media in a ball mill is typically steel or ceramic balls of varying sizes, depending on the feed size, work index of the ore and the size reduction and distribution required in the dischargeBall Mills and Ball Charging Bulk Handling Technologies

Optimizing Grinding and Regrinding Capacity in Mill Design

2019年4月25日 Conversely, in the case of an anticipated future decrease in mill feed rate and increase in grade (as in a planned future conversion from open pit to underground mining), overall optimization may well indicate a constant grinding capacity in terms of installed kilowatts and equipment, but not in terms of feed tonnage2023年8月28日 Ball mills are cylindrical devices used to grind materials such as ores, chemicals, and ceramics In the copper mining industry, ball mills are primarily used for grinding copper ores into a fine powder, enabling further beneficiation processes The size and efficiency of a ball mill directly influence the liberation of valuable minerals from Copper Ball Mill: A Comprehensive Guide Bellian Mining 2024年10月28日 Laboratory Mineral Processing LatticeType Ball Mill with Output Size 200mesh, Find Details and Price about Lab Ball Grinder Ball Mill Grinding Machine from Laboratory Mineral Processing LatticeType Ball Mill with Output Size 200mesh Jiangxi Victor International Mining Equipment Co, Ltd Capacity: Feed size: Output size: Power Laboratory Mineral Processing LatticeType Ball Mill with Output Size 2024年10月25日 Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency One reason may be the improper design of the grinding chamber, which affects the flow of materials and reduces grinding efficiency Additionally, worn or damaged liners can hinder the grinding process by reducing the effective impact Inventory Of Common Faults And Solutions Of Mining Ball Mill

An EnergyT75 Size Reduction Model for Ball Mills Mining,

2022年12月22日 In a series of Julius Kruttschnitt sizedependent breakage models, the cumulative percentage passing 1/10 of the initial size is used as a fineness indicator for scientific research and the selection of grinding equipment However, in industrial practice, it is quite customary to use the mass percentage passing 75 μm as the indicator In this paper, based on The grinding media is an important part of the ball mill for grinding ore and needs to be checked for wear If there is wear, it should be replaced in time 2 Check the sieve The sieve is part of the discharge port of the ball mill and needs to be checked Ball Mill Maintenance Process and Methods MiningpediaHighest quality grinding media balls Small / large size lab scale ball mill machine / grinding ball mills Contact Directly Get Quotes!! Wholesaler, Suppliers and Exporters, Manufacturer Aimil Mining, Minerals, Metals Mining, Minerals, Metals Laboratory Ball Mill 5 Kg capacity (AIM 441) Laboratory Ball Mill 10 Kg capacity (AIM Laboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20 Kg Capacity Request a quote to customize a ball mill grinder for your application Ball Mill Drums for Size Reduction Businesses across industries work with materials that come in large chunks or frequently clump together Ball mill drums offer an efficient and inexpensive way to grind materials down to a more usable size, often as fine as 2575 micronsHighQuality Ball Mills for Efficient Grinding Pulva

Grinding Media in Ball MillsA Review ResearchGate

2024年1月13日 Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in 2017年2月20日 All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material Grinding can be undertaken in many ways The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drumGrinding Mill Design Ball Mill Manufacturer2018年4月8日 Referring to Table VI the L/D can be between 175 and 20 or even greater Referring to Table VII a 305 meter (10 foot) by 305 meter (10 foot) overflow ball mill with a 40 percent by mill volume ball charge, new liners and 50 mm (2″) balls draws 491 HP Using equation 5 there will be a loss of 055 Kw (074 Hp) per metric tonnes of ballsHow to Size Design a Regrind Ball Mill 911Metallurgist2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the Ball mill: Principles, construction, working, uses, merits, and

.jpg)

Ball Mill MadeinChina

China High Capacity Stone Ball Mill Grinding Machine US$ 1000050000 / Piece 1 Piece (MOQ) Henan Hongke Heavy Machinery Co, Ltd Outlet Size: 80325 Mesh 1 / 6 Favorites Discover the perfect Mining Mill addition with our Ball MillWholesale purchases of mining mills provide cost savings due to bulk ordering, streamlined procurement 2023年4月23日 A comparison of the grinding media is given together with the knowledge gaps that still need to be bridged to improve the quality and performance of grinding media used in ball mills(PDF) Grinding Media in Ball MillsA Review ResearchGateThe interplay between these forces produces the high and very effective degree of size reduction of the planetary ball mill Across International geardrive 4station planetary ball mills have builtin, reverse and timing functions High energy ball mills grind down material to Ball Mills: Lab Equipment Grinding Machines, FeaturesVarious capacity of dry ball mill for sale Dry ball mill machine with even discharging and low failure rate The finished material of the dry grinding ball mill is dry powder, no moisture content, no need for air drying, Capacity(t/h) Output Size(mm) Rotate Speed(r/min) Grinding Media Load(t) Motor Power(kW) Weight(t) φ900×1800: 0652:Dry Ball Mill for Sale Buy Dry Grinding Ball Mill with Best Price

Used Ball Sag Mills for Sale Mining Surplus Record

Search a huge mining inventory of used ball, pebble, sag, and grinder mills for sale today! AllisChalmers, Metso, Hardinge and more! Get updates for newly added Grinding Mills Ball, Pebble, Sag, Mining manufactured by Kurimoto Iron Works Ltd, 1969 Rated at 1020 ton per day capacity; no motor, balls or liners for this unit