Safe Practices In Rocks Crushers

.jpg)

Site safety and safer aggregate crushing operations Quarry

2020年4月17日 There are many key priorities to consider when ensuring overall site safety and safer crushing operations Safety requires proactive intervention to prevent workplace accidents Each company or site should have clear safety guidelines outlining best practices for the entire 2024年10月27日 Use these tips on crushing and screening equipment best practices to help keep your worksites safe and productive: 1 Create and Follow Safety Protocols Having established safety protocols helps keep employees Best Practices for Crushing and Screening 2024年8月7日 Whether you’re operating rock crushers or handling other heavy machinery, it’s important to have effective safety practices in place to protect yourself and your coworkers In this essential guide, we’ll explore some key Effective Safety Practices for the Aggregate 2020年6月12日 There are many ways that a careless employee could potentially face harm around aggregates equipment, but a few simple safety tips can help improve jobsite safety for crushing and screening operationsTop safety tips for working around crushing and

.jpg)

SAFE WORK PROCEDURE FOR Crushing Operations

2021年7月28日 Safe work procedures (SWPs) are a written stepbystep set of instructions on how to complete a specific task safely It must clearly identify the steps required to complete 2023年5月30日 Rock crushing and screening equipment present significant hazards in the aggregate industry These substantial machines can be unforgiving if not handled with the utmost respect and care Prioritizing safety is essential, Top Safety Tips For Crushing Screening 2023年9月2日 Safety practices are central to aggregate crushing to protect worker welfare and create a safe work environment Employers can reduce potential risks and improve safety by implementing hazard identification, Safety Practices Required in Aggregate Crushing 2022年10月27日 Here are eight crusher equipment safety tips for working with, cleaning up after and ending the operation of crushers 1 Make Sure the Operator Is Fully Trained When an 8 Tips for Crusher Safety StewartAmos Equipment Company

.jpg)

6 ways to improve crushing safety Metso

2020年5月4日 To that end, let’s look at six ways to prevent safety incidents Each of these should be watched for, encouraged, and, as much as possible, enforced Safety starts with a mindset: unsafe practices or conditions must be 2023年5月18日 To ensure the safety of personnel and assets, it's crucial to implement effective safety measures This article explores ten ways to improve crushing safety, helping 10 Ways to Improve Crushing Safety Today sbmchina2017年8月21日 Safe Work Practices Revision Date: June 1, 2017 Origination Date: Chapter 3 Page 39 Power Tools 34 Power Tools General Safety Rules Each power tool has its own unique safety hazards and these must be taken into consideration with each tool used There are; however, general procedures that do apply to all power tools TheChapter 3: Safe Work Practices wapitigravelca2023年5月30日 Remember, safety isn’t just about rules and regulations It’s about protecting lives and ensuring everyone gets to go home at the end of the day At Mellott, our wealth of experience working on rock crushers equips us Top Safety Tips For Crushing Screening

.jpg)

Clearing Blocked Crushers Health and Safety Authority

Farm Safety Code of Practice Risk Assessment document; Code of Practice for the Design and Installation of Anchors; In autogenous crushers, the rock to be crushed also provides the crushing force Crushing is accomplished by the tumbling action of the rock Flexible crushing circuits can be constructed so that hard and soft rock, can be 2023年12月16日 Plastic crushers play a vital role in waste management and recycling processes, offering an efficient solution for reducing plastic waste to manageable sizesWhile these machines contribute significantly to sustainability, it is crucial to prioritize safety during their operation This article outlines best practices to ensure the safe and responsible use of plastic Safety First: Best Practices for Operating Plastic Crushers2024年9月17日 For tough rock, rock grinders and rock crushers from RockZone Americas deliver the precision and power needed to handle the job safely and efficiently Ready to mitigate those risks? These protective systems help to control the slope and width of trenches, preventing caveins and keeping the site safe What is the best safety practice in or How to Mitigate the Risk of Rock Excavation2017年7月23日 Roll Crushers Single roll crushers, shown in Figure 7, use shearing action to break soft rock The main part is a knobbed roll where the knobs extend 3 to 4 inches beyond the roll surface Rock is caught between the roll and the stationary breaking plate where it is continually hit and pushed by the roll knobsRock Boulder Crushers 911Metallurgist

SAFE WORK PROCEDURE FOR Crushing Operations

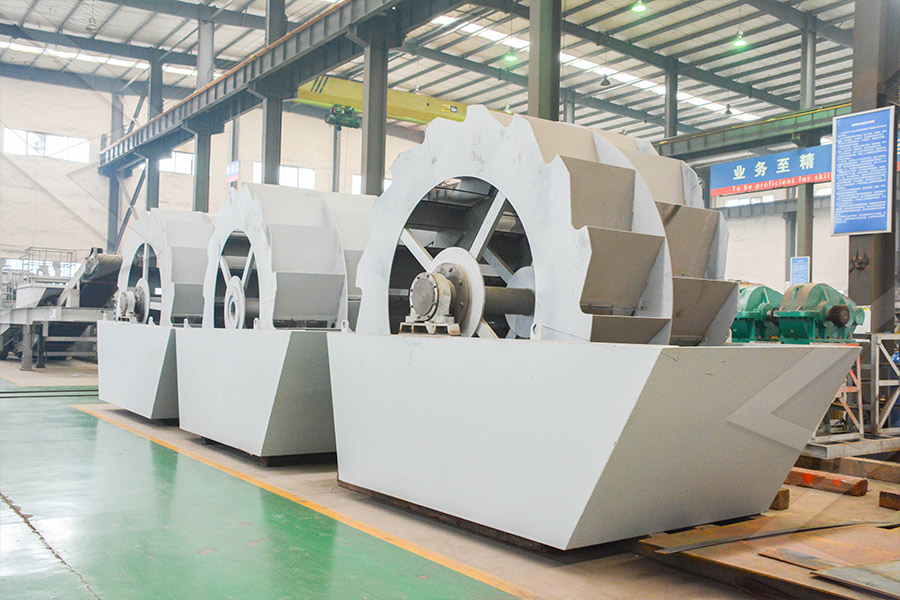

2021年7月28日 General Safety 1 Document the daily inspection of the equipment in the pre start up book 2 The safety of persons involved in installing, operating or maintaining the equipment can be affected by many factors Some of the factors that can affect the safety of the workplace are: • The location and configuration of the equipment2024年8月18日 These crushers come in several types, including jaw crushers, cone crushers, and impact crushers, each uniquely engineered to crush different types of rocks from marble to granite and limestone Mini rock crushers are particularly beneficial in limitedaccess job sites due to their mobility, performance, and safety featuresPortable Rock Crushers for OnSite Crushing Certified MTP 2019年4月8日 The US National Institute for Occupational Safety and Health (NIOSH) is conducting a crosssectional survey of equipment sound levels and worker noise exposures in the stone/aggregate mining Noise and Vibration Control in Crusher Plant Activities to Enhance 2023年9月28日 Safety is paramount when troubleshooting and maintaining rock crushers Always follow proper safety protocols and consult with experienced personnel if needed, especially for more complex issues If you encounter problems beyond your expertise, consider involving a qualified technician or contacting the manufacturer’s support for assistanceTroubleshooting Basic Issues in Rock Crushers Promaninfi

.jpg)

Quarries health and safety guide WorkSafe Victoria

Serious or fatal risks to health and safety in quarries often include: being engulfed or struck by soil and rock as a result of working near or on unstable ground; getting struck by moving plant such as excavators, trucks or light vehicles; becoming entangled in fixed plant, such as conveyors, crushers and screens; falling from height or on the 2024年8月14日 Impact crushers are used to reduce the size of ore particles for further processing They are used as secondary crushers after jaw or gyratory crushers Recycling Jobs Recycling operations are helped greatly with impact crushers by breaking down demolition debris into reusable aggregatesImpact Rock Crushers: A Comprehensive Overview2024年8月7日 The Importance of Safety in the Aggregate Industry When it comes to working in the aggregate industry, safety should always be at the forefront of your mindWhether you’re operating rock crushers or handling Effective Safety Practices for the Aggregate 2018年2月16日 Each company or site should have clear safety guidelines outlining best practices for the entire site, as well as when working with crushers Before even stepping on site to work with your site’s crusher, employees and operators must be trained on all safety procedures of your site and crusherEnhancing safety around crushers Pit Quarry

.jpg)

Crushing Operation yourACSAca

2023年5月16日 Safe Work Practice 0012 SWP—0012 Page 1/1 The information presented in this publication is intended for general use and may not apply to every circumstance It is not a definitive guide to OHS legislation or industry standards This does not relieve persons using this publication from their responsibilities under applicable legislation2024年10月24日 Types of Stone Crushers Available in Tanzania Jaw Crusher Jaw crusher is widely used for primary crushing These machines handle large rocks and provide a reduction ratio of 3:1 to 6:1 Heavyduty construction makes jaw Stone Crusher Machine Price Analysis in Tanzania Zenith 2023年2月21日 Aggregates: Jaw crushers are commonly used to crush aggregates such as gravel and sand for use in the construction industry Hard rock: Jaw crushers are often used to crush hard rock ores such as gold and silver ores, copper ores, and iron ores Recycling: Jaw crushers can also be used to recycle concrete, asphalt, and other construction materialsThe Ultimate Guide to Jaw Crushing Machines: TypesConduct regular safety meetings and refresher training sessions to reinforce safe work practices and ensure compliance with safety regulations Equipmentspecific training: Provide thorough training on the safe and proper operation of all equipment used in Crushing and Screening Best Practices: Maximizing Efficiency

.jpg)

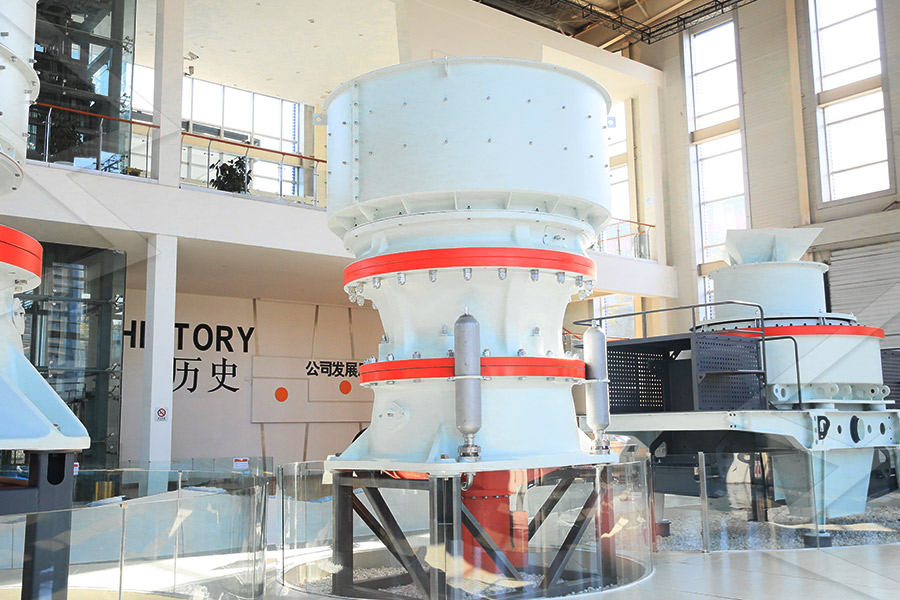

Selecting the right crusher for your operations Quarry

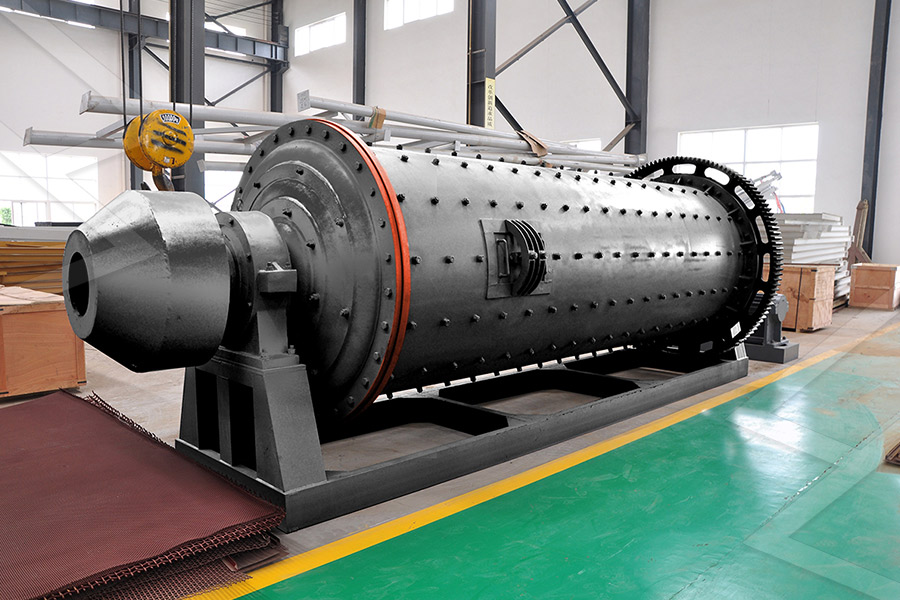

2020年3月19日 Cone crushers, which are also known for their ability to crush hard, abrasive ores and rocks, break material by squeezing or compressing it between convex and concaveshaped surfaces Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of 2023年10月13日 Laboratory rock crushers are essential tools in various research and analytical applications They are used to crush, grind or pulverize rocks and minerals to prepare samples for analysis We currently have several different types of laboratory rock crushers, each with its unique features and benefits 1 Laboratory jaw crusher:Safety Instructions For Operating Laboratory Rock Crushers2024年10月31日 However, jaw crushers also have some disadvantages For example, jaw crushers tend to be much larger and more expensive than other types of rock crushers, which can limit their use in specific applications Jaw Jaw Crusher: What Is It How Does It Work?2023年8月17日 From rocks to resources, crushers are pivotal in the transformation process that drives modern industries These versatile machines, each with its unique working principle, allow raw materials to be refined, What are Rock Crushers? How do Crushers

.jpg)

Rockbreaker Attachments In Mining: Enhancing Efficiency And Safety

2024年5月17日 Rockbreaker attachments are hydraulic tools mounted on excavators, backhoes, or stationary booms to break rocks and boulders into smaller, more manageable pieces They are essential in mining operations for several reasons: Primary Breaking: Rockbreakers are used to break oversized rocks that are too large to pass through the crushers This is Rules and safe operating procedures should be established for each task and the operators must be properly trained before being authorized to do this work The practice of using of steel bars to lever rocks in blocked crushers has a high accident rate Hand and back injuries are common but far more serious harm can occur, particularly if an AMIT 129: Lesson 12 Crusher and Mill Operation Safety2024年6月28日 Rock crushers, specially designed machines, play a vital role in industries like mining, construction, and recyclingThey are responsible for breaking down large rocks into smaller, more manageable pieces for different applications There are two main groups of rock crushers: compressive crushers, which include primary crushers used in the first stage of the Crusher Rock: Exploring the Types of Rock CrushersIn 2010 and in recognition of our procedures and practices, the Saif Bin Darwish Crushers were awarded registration against the International Standard BS EN ISO 9001:2008 by Lloyds Register Quality Assurance From the very early stages of enquiry we closely interact with our clients to firmly establish project requirementsqaqc Crushers in UAE Quarries in UAE Crushers in

.jpg)

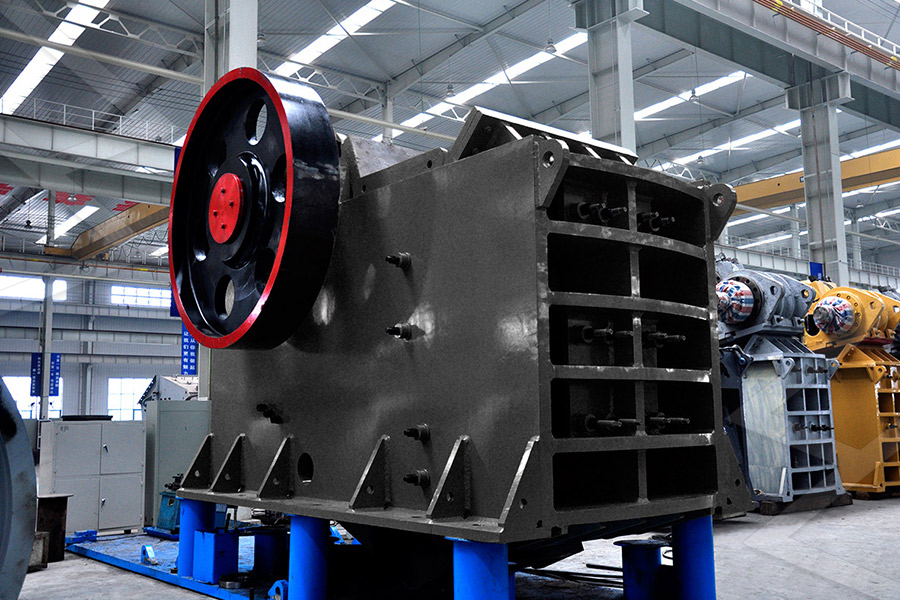

Choosing the Right Crusher: Types, Features Applications

2024年10月26日 You will often see crushers being used to break up asphalt for roadwork tasks or demolition projects There are many different sizes of rock crushers, allowing you to meet varying capacities for specific jobs You can find primary and secondary crushers for achieving coarse products, and tertiary or quaternary crushers for fine particle products2023年9月30日 Importance in the Construction Industry Primary Crushing: Jaw crushers are fundamental tools in primary crushing processesThey are capable of handling a variety of materials, including hard rocks and ores In construction projects, primary crushing ensures that excavated rocks are reduced to a size that can be processed furtherWhat is the role of 'jaw crusher' in the construction industry 2014年7月18日 acceptable safety measures are contained in this publication, or that other, or additional, (la rge clay balls, roots, v ery larg e rocks, etc), separates sand f rom grav el, and then separates the g ravel into di fferent si zes Spr ay bar s wash the g ravel as it passes throug h the scr eeni ng crushers, and final rinse screening SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB 2023年6月7日 Operators should receive training on equipment handling, safety procedures, and maintenance practices Electric rock crushers are transforming smallscale operations by offering powerful and eco Electric rock crushers for smallscale operations LinkedIn

.jpg)

Electric Rock Crushers Explained: Features, Benefits, and Uses

2024年5月20日 Electric rock crushers are more efficient, more sustainable, and better for the environment than traditional dieselpowered rock crushers There is a growing demand for better environmental practices and sustainability in the manufacturing and industrial sectors This is why so many companies look at alternatives to fossil fuels to power 2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE 2023年4月27日 Limestone: A common rock used in construction, small rock crushers can crush limestone into various sizes for building foundations, road bases, and concrete productionPower of Small Rock Crushers in Australia LinkedInRock crushers break rocks into smaller pieces to make gravel, improve a road, or apply rock to a building We also control our process with industry best practices and mine safety regulations to protect everyone onsite Click the link below to continue reading about our rock crushing safety procedures Learn More About Our Safety ProceduresRock Crusher Pontotoc

5 Safe Machinery Practices for Miners DOL Blog

2024年4月4日 5 Safe Machinery Practices for Miners Filed in Safety and Health Mining Español roof/rock bolting machines, milling machines and haulage equipment Under the Mine Act, mine operators have ultimate responsibility for the safety and health of their miners There’s an ongoing need for operators and others in the mining community to 2024年10月31日 It can process rocks, stones, and various recyclable materials such as concrete, asphalt, and glass Asphalt crushers reduce the chunks or pieces of asphalt by grinding them into smaller particles so they can be reused in road construction projects The end product is aggregate material often used for road bases, parking lots, and drivewaysAsphalt Crusher: Best Practices For Crushing ScreeningThe Saif Bin Darwish Crushers facility has the capability to produce different sizes of aggregates, rocks and rock armour as per specific customers’ specifications and quantity requirements All rock production fully complies with the appropriate International Standards (BS, ASTM, AASTHO, CIRIA etc) The production process involves a series of specialised stages depending upon Crusher Production Crushers in UAE Quarries in UAE Crushers 2024年10月29日 This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers This guidance cannot cover every risk and is not comprehensiveSafe operation and use of mobile jaw crushers HSE