Flow Sheet Diagram Of Chromite Ore

Process flow chart for the production of a chromium salt from chromite ore

Download scientific diagram Process flow chart for the production of a chromium salt from chromite ore from publication: Advances towards a Clean Hydrometallurgical Process forFigure 10 presents the photograph of chromite sinters on a tray The molten phases bonded Flow sheet for chromite sintering in sinter pot2011年4月1日 This article reviews the major process flow sheets in practice for the recovery of chromite values from various types of ores and critical issues related to chromite ore Chrome ore beneficiation challenges opportunities – A Contribute to jgw2023/sbm development by creating an account on GitHubsbm/sbm process flow sheet for chromitemd at main

.jpg)

Flow sheet for chromite sintering in sinter pot

Figure 10 presents the photograph of chromite sinters on a tray The molten phases bonded well with the solid phases to produce porous (and partly reduced) sinter mass The strength of theChromite Gravity Recovery Process Flowsheet using ineral MJigs 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with Chromite Process Flowsheet 911MetallurgistChromite ore can be classified into three categories: high grade chromite ore containing 50% Cr2O3, sub grade chromite ore containing 35% to 40% Cr2O3 and low grade chromite ore containingSample preparation flow sheet Download 2010年7月14日 Illustrative Flow Sheet of the Clean Production Process of Chromic Oxide For the trivalent chromium in the chromite ore, it is firstly converted into hexavalent chromium as A CLEAN PRODUCTION PROCESS OF CHROMIC OXIDE

.jpg)

Chromite ore beneficiation: prospects and challenges

2023年1月1日 Around 90% of the mined chromite ore is converted into different grades of ferrochrome, while about 80% ferrochrome produced of mainly highcarbon or charged 2020年5月19日 conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: Communition (for preparing the material for the subsequent unit operations) Process optimization of a chrome ore gravity 2018年1月1日 The original “Panton process’’ was developed for the highchromite Panton Sill ore in EP T oxidized mineralisation which was problematic as the deposit size and remoteness could not justify the erection of a smelter, (PDF) A conceptual hybrid process flowsheet for 2020年4月1日 It is observed that percentage recovery of Cr2O3 depends upon tilt angle, water flow rate and preheat treatment of chromite ore Preheat treatment of chromite ore plays a vital role in gravity Process optimization of a chrome ore gravity

.jpg)

Chromite ore beneficiation: prospects and challenges

2023年1月1日 Sukinda flow sheet for chromite ore beneficiation 354 Challenges in chrome ore gravity concentrator Particle densitybased separations are commonly used to concentrate minerals like chromite, tin, heavy mineral sands, iron ore coal, etc These processes operated in parallel or multistage circuits Speciation diagram of Cr(VI) (Dionex A conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: > Communition (for preparing the material for the subsequent unit operations) > Concentration (classification and beneficiation) The Process optimization of a chrome ore gravity 2018年2月21日 About 80% of the worlds’ reserves for platinum group metals (PGMs) are in South Africa’s Bushveld Igneous Complex Processing of PGM involves comminution, flotation, smelting, converting, base metals refinery and precious metals refinery Due to increasing chrome content in the feed and the challenges associated with operating high chrome feed, alternative Extraction of Platinum Group Metals IntechOpenTypical Chrome Beneficiation Flow Sheet Multotec specialises in chrome beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per tonTypical Chrome Beneficiation Flow Sheet Multotec

Technology Innovations in the Smelting of Chromite Ore

2021年8月5日 Keywords: Chromite ore, Ferrochrome, Submerged arc furnace, Outokumpo, Premuse 1 Introduction The mineral chromite, with chemical composition FeCr 2O4 (ferrous chromic oxide), is a submetallic mineral belonging to the spinel group (with a generic formula of R +2 OR +3 O 4) It is the only economic mineral mined for 2023年11月26日 The next stage in the chrome plant process flow is ore extraction There are several methods employed to extract chromite ore from the ground, including surface mining and underground mining Surface mining involves the removal of soil and overburden to expose the ore, which is then extracted using heavy machinery, such as excavators and loadersStepbyStep Guide: Chrome Plant Process Flow Explained2020年5月25日 conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: Communition (for preparing the material for the subsequent unit operations) Concentration (classification and beneficiation) The beneficiation process flow sheet varies from location to location according to the ore characteristicsProcess optimization of a chrome ore gravity 2019年5月9日 Fluxing of South African chromite ore with colemanite by MW Erwee, IJ Geldenhuys, MB Sitefane, and M Masipa 03BF7AEA South African chromite ores are smelted using SiO2 and CaOcontaining fluxes, normally as quartz and limestone respectively The purpose of SiO2 is to lower the melting point of the ore, while CaO is added to ensure that thev118n6a15 Fluxing of South African chromite ore with

Process optimization of a chrome ore gravity

2024年7月23日 Figure 3—Conventional process flow sheet for chromite ore beneficiation Figure 4—Beneficiation of Indian chromite ores ˙ ˛˘ ˙ 264 MAPRIL 2020 VOLUMEPercentage chromium oxide is improved upto 49% with 63% of recovery while raw chromite ore contained only 342% Cr2O3 Author concluded that separating the materials into size fraction without Mineral composition of the chromite sampleDownload scientific diagram Flow sheet of the proposed process route for treating lowFe(II) chromite from publication: Cleaner Production of Chromium Oxide from Low Fe(II)Chromite Sulfuric Flow sheet of the proposed process route for 2008年1月1日 Some amounts of magnetite and chromite exist in the ore together with sulphide and oxide type nickel minerals The ore sample contains 132% Ni, 1079% SiO2, 7839% Fe2O3, 13 g/t Ag, and 10 g/t AuProcess flowsheet development for beneficiation

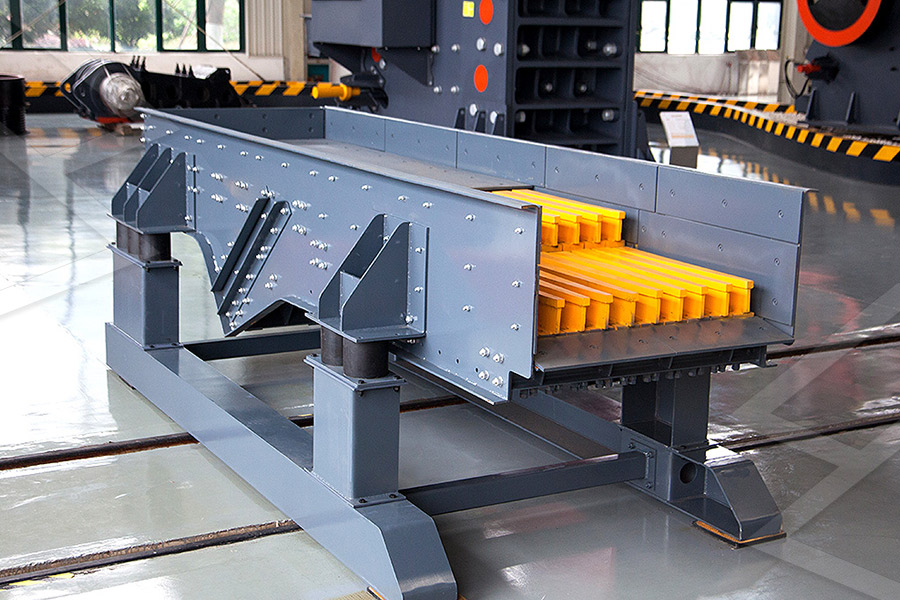

Ore drying and preheating model flow sheet Download Scientific Diagram

Download scientific diagram Ore drying and preheating model flow sheet from publication: Evaluating pretreatment and smelting options with EMSIM to improve production efficiency In light of 2016年4月12日 Chromite Grinding The 36″x 8′ Adjustable Stroke Ore Feeder is used to accurately control feed of crushed ore to the grinding section Before it is fed to the 4’x 8′ Peripheral Discharge Rod Mill, the minus ¼” chrome ore is removed from the grinding circuit by means of a 4’x 12′ Dillon Vibrating ScreenChromite Beneficiation Process 911Metallurgist2017年8月28日 chromite concentrate with 4529wt% Cr2O3 and a Cr:Fe mass ratio of 185 can be produced from these lowgrade chromite ore beneficiation plant rejects Keywords: tailings; mineralogy; chromites; beneficiation 1 Introduction Chromite is the main source of chromium metal and an important raw material for the production of stainless steel,Quantitative mineralogical characterization of chrome 2010年7月1日 Effect of chromite ore particle size on chromium extraction was studied at a temperature of 370 °C, liquidtoore ratio of 4:1, mass content of NaNO 3 of 25% in liquid, and oxygen flow rate of 1 L/min The chromite ore with particle size of 58–74 μm, 45–58 μm, and 25–45 μm was used, and the results are presented in Fig 9 It is Decomposition of chromite ore by oxygen in molten

.jpg)

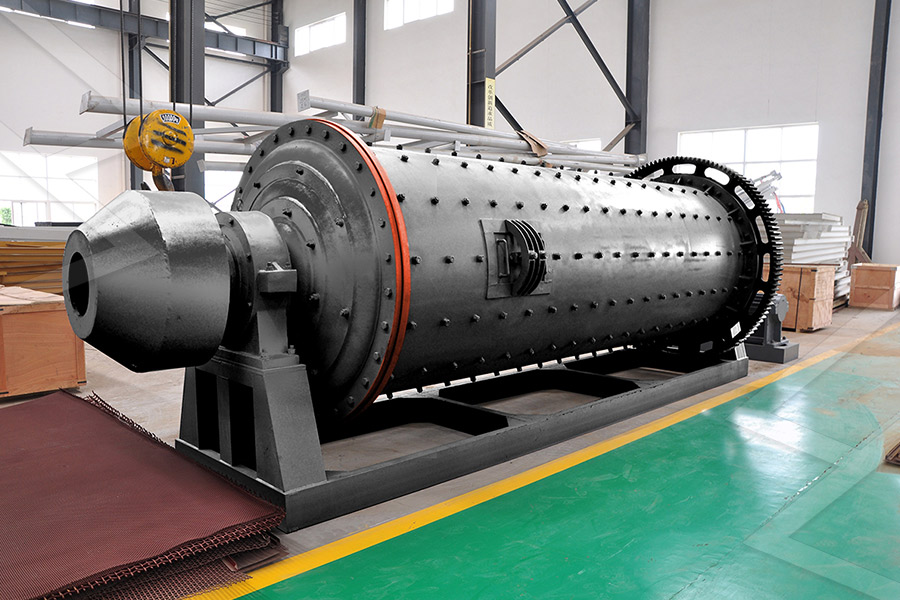

Performance optimization of an industrial ball mill for

2017年3月9日 chromite in the tailing, etc) of the beneficiation circuit The ROM ore properties (size distribution, grindability, liberation, physical properties, etc) vary significantly between the different ore layers (northern band and mid band) So it is necessary to revisit and optimize the existing grinding circuit based on the ore characteristics2015年1月12日 • The UG2 Reef, a chromiterich reef, is more consistent, but lacks Merensky’s high yield of Gold, Copper and Nickel byproducts In the last decade, PGM miners recover chromite as a separate product • Platreef is a wider reef with lower PGM values, but higher base metal content (c 5 times) 5 Overview of PGM ResourcesOVERVIEW OF PGM PROCESSING Anglo American 2024年1月10日 Chromite ore processing tailings and lowgrade manganese ores are typically considered waste due to their limited or negligible utility, leading to environmental and storage concerns From the Ellingham diagram for oxides it can be understood that the ease of reduction of oxides is in Güney A, Onal G, Çelik MS (1999) A new flow sheet Valorization From Waste: Combined Reduction of Chromite Ore 2018年7月10日 Production of FerroChrome satyendra; July 10, 2018; 9 Comments ; carbothermic reaction, charge chrome, chromite ore, Cr, Direct arc furnace, Fe, FeCr, SAF,; Production of FerroChrome Ferrochrome (FeCr) is an alloy comprised of iron (Fe) and chromium (Cr) used primarily in the production of stainless steelProduction of FerroChrome IspatGuru

.jpg)

PROCESS FLOWSHEET DEVELOPMENT FOR BENEFICIATION OF NICKEL ORE

2007年11月14日 The ore sample contains 132% Ni, 1079% SiO 2, 7839% Fe 2 O 3, 13 g/t Ag, and 10 g/t Au The ore sample is constituted of about 70% magnetite, 15% sulphide minerals, and 5% chromite and iron oxides, as well as 10% gangue minerals Nickel mineralization in the ore such as pentlandite, violarite, millerite awaruite, and asbolanewas determinedThe feed to the BCL concentrator is made of the ore from Phikwe No3 shaft, Selebi shaft and Selebi North shaft The receiving bin of the concentrator has daily throughput of 7869mt live capacity 1: BCL ore preparation flowsheet Download The present study investigates the optimization and advanced simulation of the flotation process of coarse particles (–425 + 106) using micronanobubbles (MNBs)Flowsheet of iron ore flotation process with zoom on single 2017年11月6日 The beneficiation of platinum group metals (PGMs) from pristine (unweathered) sulfide ores has conventionally been conducted through froth flotation, which typically achieves platinum recoveries of over 85% The achieved successes of PGM concentration by flotation from the pristine sulfide ores are largely due to the occurrence of PGMs in close association with Potential Processing Routes for Recovery of Platinum Group

.jpg)

Characterisation of South African Chromite Middle

2020年7月27日 The mineralogical analysis in the ore showed that the occurrence of chromite phases in the ore is very similar in all Middle group seam layers as indicated in Figure 3 The six endmember compositions that combine to form chromite are hercynite (FeAl 2 O 4), spinel (MgAl 2 O 4), Fechromite (FeCr 2 O 4), magnesiochromite (MgCr 2 O 4), magnetite 2019年5月1日 This article reviews the major process flow sheets in practice for the recovery of chromite values from various types of ores and critical issues related to chromite ore beneficiation(PDF) Reduction of Kemi chromite with methaneDownload scientific diagram Chromite prereduction model flow sheet from publication: Evaluating pretreatment and smelting options with EMSIM to improve production efficiency In light of Chromite prereduction model flow sheet Download Scientific Diagram2019年8月29日 Sensor‐based ore sorting applies at various points in the process flow diagram and is suitable for waste elimination, for material diversion into different process lines, for the production of (PDF) Sensor‐Based Ore Sorting Technology in Mining

Chrome ore beneficiation challenges opportunities – A

All the unit operations were operated individually rather than a flow sheet Subgrade chromite ore with Cr2O3 of about 385% of Sukinda region of India, can be upgraded to a marketable chrome concentrate of 53–54% Cr2O3 with a recovery of about 58–60% and tailing loss of around 14–1639% of Cr2O3, by using wet shaking tables in the 2014年9月10日 The chemical compositions of chromite ore and the residues were determined by ICPOES (PE Optima 5300DV, PerkinElmer) The mineralogical phases of chromite ore and residues were determined with Xray diffraction (XRD, Phillips PW223/30) The SEMEDS results of chromite ore and residues were determined with SEM (FEI MLA 250, Australia) equipmentA new metallurgical process for the clean utilization of chromite ore Download scientific diagram Chromite smelting DC furnace model flow sheet from publication: Evaluating pretreatment and smelting options with EMSIM to improve production efficiency In light Chromite smelting DC furnace model flow sheetPercentage chromium oxide is improved upto 49% with 63% of recovery while raw chromite ore contained only 342% Cr2O3 Author concluded that separating the materials into size fraction without Table 1 Size wise chemical analysis of the

A cleaner method for preparation of chromium oxide from chromite

2017年1月1日 An EhpH diagram of Cr–Fe–H 2 O at 160 °C was produced • Stability of chromite in oxidizing solution is related to its Fe(II) content • A decomposition mechanism for chromite was proposed • Fe, Mg and Al were effectively separated from leachate • Chromium oxide product with about 98% Cr 2 O 3 was preparedDownload scientific diagram The simple flow sheet of recover of platinum group metals (PGMs) by hydrometallurgical process (Dong et al, 2015) from publication: Metals smeltingcollection The simple flow sheet of recover of platinum group metals 2014年10月15日 The optimized tabling conditions suggested by BBD are 8° tilt angle, 4 L∙min1 water flow rate and temperature for preheat treatment of raw chromite ore at 44372℃BENEFICIATION OF MAGNETITE RICH CHROMITE ORE WITH MAGNETIC SEPARATION2017年1月1日 The schematic process flow sheet of the COB plant grinding circuit is shown in Figure 1 The ball mill is in closed circuit mid band lowgrade chromite ore is softer and more friable(PDF) Performance optimization of an industrial ball mill for chromite

.jpg)

Macroscopic and microscopic photographs of chromite ore

The lowgrade siliceous chromite ore from Ghutrigaon, Odisha, India, containing ~ 16% Cr2O3, with Cr/Fe ratio of 197 and ~ 55% of SiO2, does not find any use in metallurgical industry and hence 2016年10月19日 A chromite concentrate with 4529wt% Cr2O3 and a Cr:Fe mass ratio of 185 can be produced from these lowgrade chromite ore beneficiation plant rejects View Show abstractPRODUCTION OF CHROMITE CONCENTRATE FROM MAGNETIC WASTES OF ORE 2009年9月15日 The reduction of chromite ore with carbon has been studied extensively in many laboratories Inert gases have been used in these investigations to control the experimental conditions However, little information is available in the literature on the influence of the gas flow rate on the rate of reduction Experiments were carried out to study the influence of the flow Carbothermic Reduction of Chromite Ore Under Different Flow