Process Limestone Crushing Equment

Limestone crushing process sbmchina

2023年1月19日 When the process starts running, the limestone is uniformly fed into the jaw crusher through the vibrating feeder for primary crushing, crushed to a certain particle size, and then sent to the cone crusher through the belt conveyor for secondary crushing, and then The Configurations of limestone crushing and sand making plants with different capacities The oLimestone Mining ProcessSBM Industrial Technology Grou2024年6月11日 Equipment Selection The selection of crushing, screening, and grinding equipment for a limestone processing plant will depend on a number of factors, including the desired product size, the capacity of the plant, and the Limestone Processing Crushing Operations and 2018年9月15日 Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as Limestone Quarrying and Processing: A LifeCycle

Exploring the process flow of 800 tons of limestone crushing equipment

2024年10月13日 The process flow of 800 tons of limestone crushing equipment per hour involves a series of steps, including feed preparation, primary crushing, secondary crushing, 2023年2月14日 Proper crushing of limestone is essential to ensure that the final product meets the necessary specifications and standards A wellexecuted crushing process also reduces Optimized Limestone Crushing Process for Increased 2024年10月25日 The limestone crushing production line is divided into three stages: coarse crushing, medium fine crushing and screening The first stage: coarse crushing The limestone Limestone Aggregates Processing SHANGHAI SANME 2021年9月9日 Configurations of limestone crushing and sand making plants with different capacities The output of common limestone crushing sand making production line is 100 Limestone Mining ProcessSBM Industrial Technology Group

.jpg)

Limestone Crushing Equipment and Production

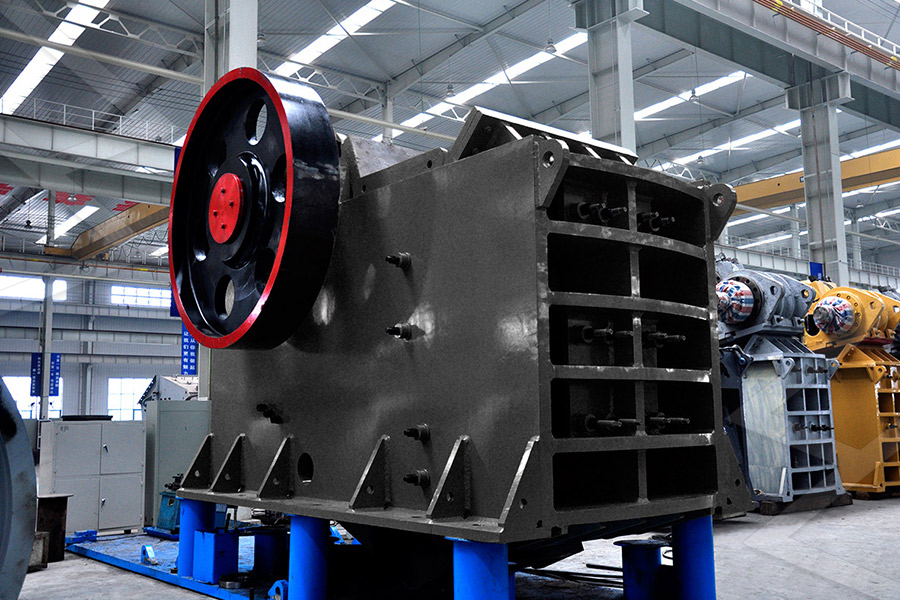

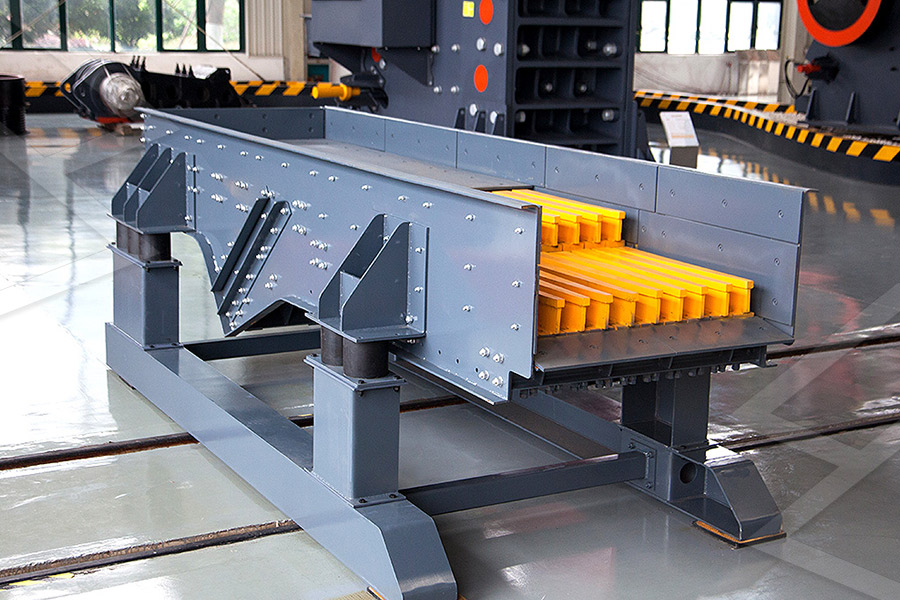

5 天之前 Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other Overview of Limestone Crushing System A limestone crushing system is designed to take large pieces of raw limestone, reduce their size, and prepare them for further processing The Limestone Crushing System miningasia2023年2月14日 The limestone crushing process involves several stages, each of which plays a critical role in ensuring that the final product meets the necessary specifications and standards Type of Crushing Equipment: The type of crushing equipment used can have a significant impact on the quality of the final product Jaw crushers and gyratory crushers Optimized Limestone Crushing Process for Increased 2024年10月7日 We provide equipment to process iron ore, coke, and other raw materials into suitable forms for steel production With decades of expertise, we specialize in providing solutions for the crushing of coal, iron ore, limestone, Mechtech Inframine Home of Superior

.jpg)

Limestone Crushing Equipment and Production

5 天之前 Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other 2023年2月13日 There are various types of limestone crushing equipment available, each with its own advantages and disadvantages In this article, we will compare the different types of limestone crushing equipment and their efficiency in the production process to help you make informed decisions Types of Limestone Crushing Equipment Jaw CrushersWhat Is The Best Limestone Crusher Limestone CrushingHammer Mills Williams manufactures a large variety of hammer mills and hammer crushers wellsuited to handle limestone crushing applications As the manufacturer holding the very first hammer mill patent to utilize midair impact crushing, Williams takes great pride in providing quality, rugged machines for many applicationsLimestone Crushers Pulverizers Williams Crusher2021年6月24日 stage process or a complete plant, we assist you with the right design for the most costeff ective crushing process We are the world’s leading supplier of both unit machines and complete aggregates processing systems Comprehensive process solutions Your system may involve a whole series of processes, such as crushing and screening Crushing and Screening Handbook AusIMM

Types of Rock Crushers Quarry Crushing Equipment Kemper

2 天之前 Do you need to process sand, gravel, minerals, rock, or other aggregate products and have not yet purchased or leased crushing equipment? There’s no question—you need to work with a capable and professional material handling equipment design and engineering company dedicated to selling, renting, and installing the best new crushers for your needs2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushing2024年2月21日 The extracted limestone is then transported to the processing plant using heavy machinery such as bulldozers and dump trucks Crushing: Once the limestone reaches the processing plant, it undergoes primary crushing to reduce the size of the rocks Large crushers, often jaw crushers or gyratory crushers, break down the limestone into smaller piecesThe process of limestone aggregate making SANDMINE2024年8月8日 For the raw material preparation system in cement process, limestone is usually crushed by twostage crushing equipment; the crushed limestone particle size is generally 20mm In order to fully improve the production efficiency of grinding system and lower grinding power consumption, "multicrush and less grinding" technology is a very DPX Fine Crusher > Crushing Equipment > Products > DSMAC

.jpg)

Top 4 upgrading tips for limestone crushing plant in lime

2024年10月12日 To Make it easy to understand, AGICO has summed up 4 essential tips to improve lime material purity in limestone crushing plant The second is the calcination equipment and calcination method according to limestone conditions 4 Tips in Limestone Preparation Process 1Limestone Types – Raw Material Selection6 天之前 Stay tuned for more exciting posts about crushing equipment! What Is A Limestone Crusher And What Are Its Uses? The machine can be used to process a variety of different materials, including concrete, asphalt, and Limestone Crusher: What Is It How Does It 2020年4月20日 Crushing is also very useful in the chemical industry for breaking down hard materials such as limestone or coal What equipment are used in crushing process? In the preindustrial era, crushers were usually Crushing in Mineral Processing Eastman Rock 2022年4月20日 Limestone crushing process Limestone or limestone are rich in resources, and the grade of raw ore can generally meet the requirements of various industrial sectors We can choose impact crusher for equipment Some stones use cone crusher for secondary crushing, but the hardness of limestone is not high Considering the problem of Limestone crushing and grinding production line SBM

.jpg)

Limestone crushing, sand making and grinding process

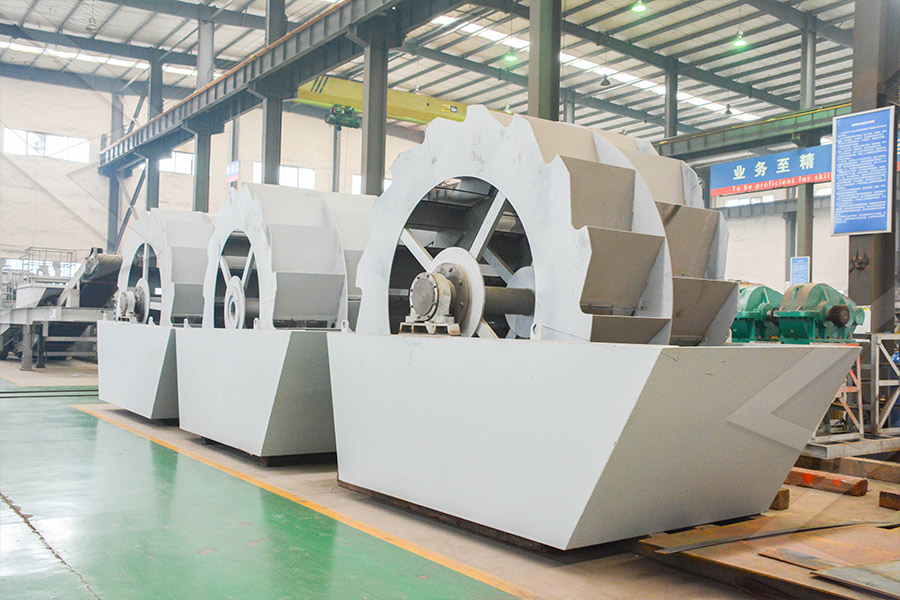

2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished 6 天之前 1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, and the Limestone Aggregate Crushing JXSC Machine2023年2月28日 Crushing is an energyintensive process that involves different types of equipment, such as crushers, screens, and conveyors Primary Crushing Primary crushing is the first stage of crushing that takes place at the mine or quarryPrimary and Secondary Crushing: Understanding the Basics2024年1月23日 The entire processing process involves the collaborative operation of these equipment, transforming the original limestone blocks through multiple stages of crushing, screening, and processing, ultimately producing limestone building materials that meet various construction needsLimestone crushing and screening production line introduction

Do’s Don’ts Of Limestone Rock Crushing Mellott

2023年3月27日 Limestone crushing is an essential part of the mining and construction industry Cone crusher parts are used for this purpose, and they come in various sizes and configurations to match different applications However, every operator should be aware of certain do’s and don’ts when using cone crushers before making any adjustments or repairs2019年10月8日 As long as the appropriate process configuration and crushing equipment selection are adopted in the crushing process, a good crushing effect can be obtained In combination with the principle of “crushing more and less grinding” in the limestone production line, it is necessary to produce the best particle size in the stage of limestone How to Process Limestone? HongXing Machinery2021年9月9日 The output of common limestone crushing sand making production line is 100200t/h, 200400t/h, 200500t/h, but with the largescale production, 800t/h, 1000t/h or even higher capacity sand making lines will become a trend Here are the configurations of limestone crushing and sand making plants with different production capacitiesLimestone Mining ProcessSBM Industrial Technology Group 2024年10月20日 800 TPH Limestone Crushing Process The limestone crushing production line primarily consists of four processes: feeding, crushing, sand making, and screening It is typically composed of vibrating feeder, jaw 800TPH TPH Limestone Crushing Process –

.jpg)

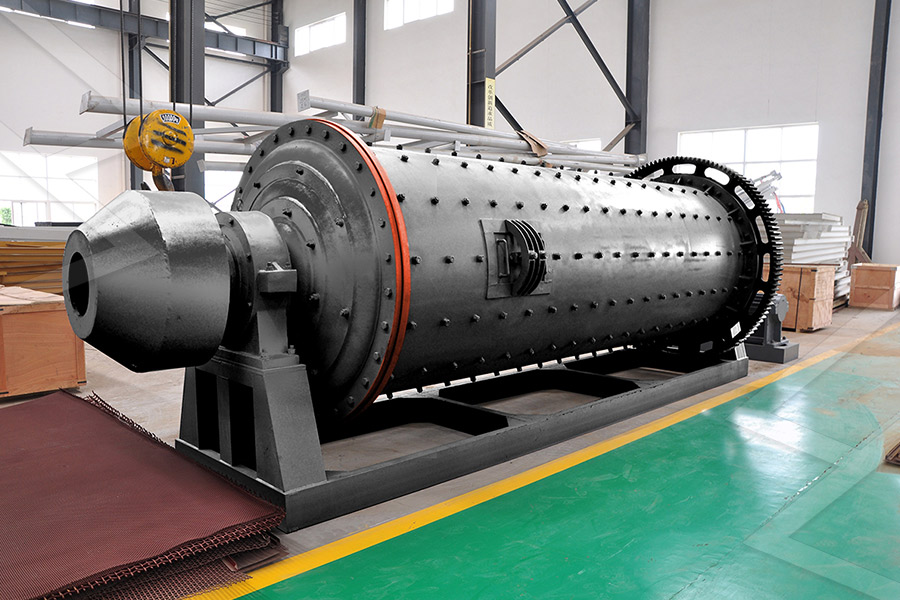

How to process limestone? saico

2024年3月27日 The main limestone processing techniques are as follows: Crushing: Breaking large pieces of limestone into small pieces for subsequent processing Commonly used crushing equipment includes jaw crusher, impact crusher, cone crusher, etc Screening: The crushed limestone is screened according to particle size to meet the needs of different uses2024年10月28日 Our fleet of mobile crushing equipment eliminates the logistical complexities and costs associated with transporting large volumes of material We bring the processing power directly to your project site, minimizing disruption and maximizing efficiency Our mobile crushers can process limestone to your exact specifications onsite Crushing Screening Construction Company Southern 2023年6月30日 The subject of this study is crushing equipment It is a complex of units designed to reduce the fraction of ore and nonmetallic solid materials crushing process to improve the calculation Modeling and Improving the Efficiency of Crushing Equipment2023年5月16日 Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase in the future, considering the exhaustion of highquality resources and severe environmental limitations The subject of this study is crushing equipment It is a Modeling and Improving the Efficiency of Crushing Equipment

.jpg)

800TPH Limestone CrushingSBM Industrial Technology Group

2024年10月12日 1 For limestone crushing, SBM provided 3 HPT300 Multicylinder Hydraulic Cone Crushers Material, after being broken by the cone crushers enters VU Modulus Control Screen for further adjustment The output material boasts excellent shape and granularity and low powder content, which totally meets all the strict requirements of the customer2024年10月12日 Limestone Crushing Process Limestone is crushed in section 1 crushing process then it is discharged into the hopper by truck, heavyduty plate feeder is placed under the hopper, and limestone is evenly fed into the singlerotor impact crusher Then crushed gravel is sent to the limestone prehomogenization silo by belt conveyorLimestone crushing and raw meal ingredients4 天之前 Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) and is widely used in various industries, such as mining industry, metallurgy industry, and construction industryMore and more customers are paying attention to this industry and invest into limestone crushers and have made great achievementsLimestone Crusher Machine: Boost Quarrying Mining 2024年8月26日 Its crushing and grinding generally adopt dry process, and the corresponding process is selected according to different application fields: For limestone used in metallurgy and road construction, the ore is generally crushed and screened and the process equipment is basically the same as the ultrafine crushing of calcite At present, most Limestone Powder Grinding Process ALPA Powder Equipment

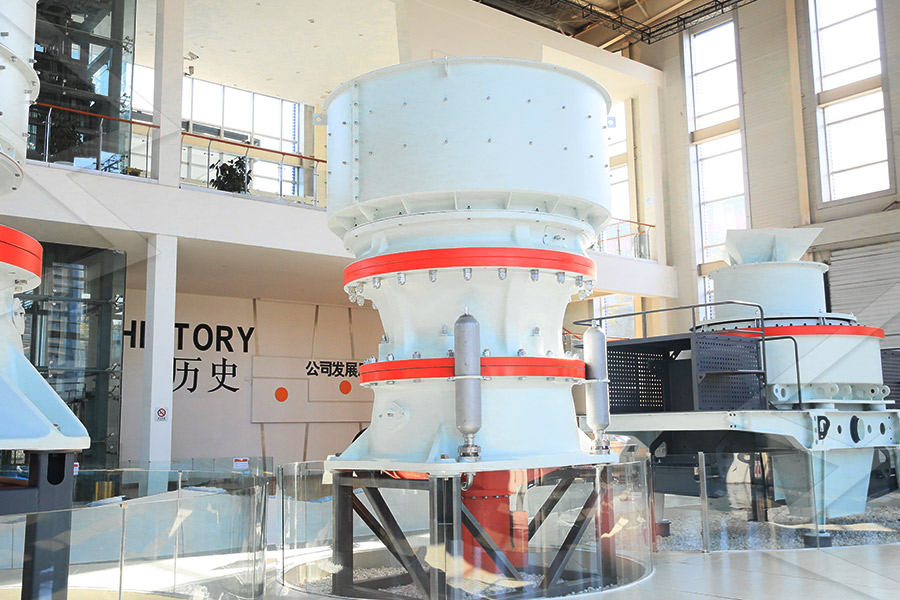

Limestone crushing equipment configuration

2022年2月15日 Jaw crusher + impact crusher (twostage crushing) 1 Jaw Crusher The limestone coarse crushing equipment has strong crushing force, and the feeding size of the equipment is 1201500 mm Because it is a first 2024年10月14日 Here, you'll discover 11 stone crushing equipment needed for stone crushing, from primary crushers to fine Sand making machines are essential in glass, silica, quartz, granite, and limestone sand production lines What Machines Do Stone Crushing Plants Need?2 天之前 Rock crushing equipment and crushers are essential for construction, mining and mineral processing Its main function is to produce sand for road construction or concrete aggregate It can crush various materials, including Stone Crusher│Ore Crushing Machine JXSC 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder

.jpg)

How to Process Limestone Environmentally? HXJQ

2022年3月22日 The dust produced in the process of limestone crushing and grinding is mainly limestone particles, whose main component is calcium carbonate The dust has an impact on the human body, plants, and soil, and the main part of the harm to the human body is particle size 10 μm dust, which is mainly harmful to the human respiratory system 2019年5月10日 Sandstone, limestone and granite are arguably the three most common aggregate used in the construction industry But these rocks each have very different hardness and abrasiveness characteristics The type of rock you need to process will dictate the types of crushers needed in the crushing circuitSimplifying the crushing process Pit Quarry4 天之前 Notes: 1 Services (installation, test run, training) : the supplier can provide basic drawings and schematic drawings of equipment installation75TPH Limestone Crushing Process in South Africa2023年2月23日 Crushing and screening equipment is a type of machinery used to process raw materials such as rocks, ores, and other aggregates for use in construction projects The equipment typically consists of a primary crusher, secondary crusher, and screening equipment, all of which work together to process the raw materials and produce the desired end Crushing and Screening Equipment: The Backbone of

Rock Crushing Equipment Rock Crushers Kemper Equipment

Rock Crusher Types Here at Kemper Equipment, we source our rock crushers from only the best crusher brands in the business We also customdesign topperforming crusher systems from the industry's best equipment that will work hard to make finished aggregate products like crushed stone, geosynthetic aggregates, sand and gravel, fertilizer, lime, specialty mineral products,